WHA Presents O2 Safety Papers at 2024 ASTM G04 Symposium

Highlights

- ASTM hosted its 16th symposium on oxygen safety in October 2024

- Three WHA team members attended the event in Prague

- WHA presented seven papers on oxygen safety at the event

In October 2024, Gwenael Chiffoleau, Nic Linley, and Brent Houser traveled to Prague for the 16th ASTM G04 Symposium on Compatibility and Sensitivity of Materials in Oxygen-Enriched Atmospheres.

They shared seven papers at the event representing the cumulative efforts of many different technical experts at WHA. The papers cover a variety of oxygen safety topics, sharing both valuable new insights and lessons learned from past failure analyses.

About ASTM G04 Committee

The oxygen safety symposium is sponsored by the ASTM G04 Committee on Compatibility and Sensitivity of Materials in Oxygen-Enriched Atmospheres.

Founded in 1975, the committee exists to facilitate international collaboration and innovation in the field of oxygen safety.

Since its inception, WHA team members have held numerous leadership positions in the organization, serving as a valuable link with the ongoing safety science at WHA.

Further reading: Learn more about ASTM G04 Committee

About the ASTM G04 Symposia

The ASTM G04 symposia provide a forum for the presentation and discussion of peer-reviewed papers on topics related to oxygen fire hazards and incidents, ignition mitigation strategies, and good practices that improve oxygen fire science and the overall safety and reliability of oxygen-enriched environments and other oxidizer systems and components. This event’s topics included:

- New Test Methods to Define Material Safety for Use in Oxygen Environments

- Ignitability and Flammability of Materials in Oxygen and Oxygen-Enriched Environments

- Combustion Rates of Materials in Oxygen and Oxygen-Enriched Environments

- Mathematical Modeling of Gas Flow and Combustion Processes in Oxygen-Enriched Environments

The gathering is designed to expand the knowledge of oxygen system designers, engineers, safety professionals, industrial hygienists, manufacturers, suppliers, and end users.

The 2024 ASTM G04 symposium was hosted October 23-24 in Prague, Czech Republic. WHA CEO Gwenael Chiffoleau, PhD, and Professor Ted Steinberg, PhD, from Queensland University of Technology (Australia) and an oxygen safety consultant with WHA, chaired the event.

Further reading: View and purchase past ASTM G04 papers.

WHA Papers

WHA’s three delegates at the symposium presented seven papers on a variety of oxygen safety topics. Their information and abstracts are listed below.

Experiences in Testing Oxygen Carrying Medical Electrical Equipment Against the Requirements of ISO 60601-1:2012 Subsection 11.2.2

Authors: Nicholas J. Linley, Hecmar Arreola, Gwenael J. Chiffoleau, Elliot T. Forsyth

It is crucial to analyze and test oxygen-carrying medical electrical equipment (ME equipment, such as ventilators, respirators, and CPAPs) for fire risks in oxygen-rich environments. This paper delves into the importance of understanding the failure modes and ignition sources associated with such equipment. Drawing on over three decades of experience in investigating oxygen-related fires and testing medical devices, the authors provide guidance for manufacturers on understanding and mitigating these risks. The focus is on ensuring adherence to international safety standards and exploring various analysis and testing pathways, from power limitations to fire consequence evaluations. This study aims to guide manufacturers in understanding the oxygen fire hazards in their oxygen-carrying medical electrical equipment and then meeting the specific requirements of IEC 60601-1:2020 Part 1-11: General requirements for basic safety and essential performance, subclause 11.2.2.1 b), for “ME EQUIPMENT and ME SYSTEMS used in conjunction with OXYGEN RICH ENVIRONMENTS.”

Statistical Curve Fitting for Burn Length Data: A Comprehensive Analysis of Metal Alloys Flammability Using ASTM G124 Tests

Authors: Nicholas J. Linley, Brent Houser, Elliot T. Forsyth, Gwenael J. Chiffoleau, E. Newton Barry

Promoted ignition data from ASTM G124 have been of great value to the industry, as they provide a fundamental basis for comparing the relative flammability of metal alloys in oxygen. In 2012, an industry-sponsored metals test and analysis program was performed with the goal of applying statistical analysis methods to ASTM G124 data to create burn curves that plotted the estimated average burn length versus pressure for a given alloy at either the standard 3.2-mm or 6.4-mm diameter rod. The results of the burn curves were presented in Forsyth, E. T. et al., “Development of Burn Curves to Assist with Metals Selection in Oxygen.”

This paper presents a methodology for improved statistical curve fitting to burn length data obtained from ASTM G124 tests. The methodology involves the use of a non-linear least squares (NLS) regression using a logistic “sigmoidal” model. The method was applied to the data previously presented by Forsyth, E. T. et al., for the alloys: 316 stainless steel, 304 stainless steel, Inconel 625, Inconel 600, and Hastelloy C-276. Additionally, a tangent line method is introduced as a way to estimate the no-burn, transition, and complete burn pressure regions of a material that has been tested. This work provides an improved approach to analyzing the burn behavior of metals using ASTM G124 data and presents new burn curves that can help to better characterize the relative flammability of metal alloys in oxygen.

Comparison of 300-Series Stainless Steels ASTM G124 Data

Authors: Brent Houser, Nicholas J. Linley, Gwenael Chiffoleau, Barry Newton

300-series stainless steels represent some of the most widely used metallics in oxygen, and their flammability in oxygen has been extensively researched at varying thicknesses and pressures. There is increased interest in the differences or lack thereof in flammability across the many types of 300 series stainless steel alloys. This paper presents recent ASTM G124 data as well as historical data on a number of 300 series materials to determine if these alloys exhibit similar flammability characteristics. The following results are presented for four alloys: 316 stainless steel, 304 stainless steel, 321 stainless steel, and 316Ti stainless steel. This work provides a better understanding of common alloys and their ability to be utilized interchangeably with no alteration of flammability.

Particle Ignition Testing at WHA

Authors: Brent Houser, Gwenael Chiffoleau, Brad Forsyth

Particle impact is a recognized ignition mechanism in oxygen systems. Characteristic elements of particle impact ignition are commonly present in components with large pressure drops (i.e., high-velocity flow), such as pressure regulators, flow control orifices, and flow control valves. WHA International, Inc. (WHA) has performed particle impact ignition testing for various programs using two types of test approaches: Transient and Steady-State, which are outlined in this presentation.

The transient approach includes rapidly introducing high-pressure oxygen into ambient pressure tubing pre-loaded with metallic particles. Metallic particles are carried by pressure surge through a straight run of tubing and allowed to impact the test article under flowing conditions. The steady-state approach includes pre-loading metallic particles and slowly introducing high-pressure oxygen up to a closed valve downstream of the test article, which was preset in an open configuration. Steady-state flow is quickly initiated by opening the valve downstream of the test article, which is intended to control the gas flow. The particle loading area is inspected posttest to ensure the flow was sufficient to propel the particles towards the test article.

WHA evaluated the likelihood of particle ignition during both transient and steady-state approaches by varying parameters such as pressure, particle size and material, orifice size (i.e., gas velocity), and geometry. Test articles included curved tubes, valves, and orifices. Particle ignition was evaluated with video and post-test inspection of test article and other regions of the test system.

WHA observed particle ignitions during tests at pressures from 70 to 276 barg (1000 to 4000 psig) and sub-sonic velocities. Differences in particle ignition activity were noted based on particle material (i.e., aluminum, 300 series stainless steel, and iron). Metallic particles were also found to ignite via ignition mechanisms other than direct particle impact during the transient testing approach.

Video: Watch a particle impact test

Particle Impact Assessment of Curved 304 Stainless Steel Tubes in Gaseous Oxygen Evaluated under Elevated Temperature and Pressure

Authors: Vasanth C. Shunmugasamy, Bilal Mansoor, Texas A&M University, Doha, Qatar and College Station, TX, USA; Gwenael Chiffoleau, Elliot Forsyth, WHA International Inc., Las Cruces, NM, USA; Nicholas J. Laycock, Qatar Shell Research and Technology Center, Doha, Qatar; Alfred Kruijer, Shell Global Solutions International BV, The Hague, The Netherlands

In the present research, materials compatibility assessment of curved 304 stainless steel (SS) tubes using particle impact (PI) testing was explored, at elevated temperature and pressure in gaseous oxygen. Oxygen preheaters comprising tubes of multiple curved diameters are known to be operated at elevated temperature (273°C) and pressure (66 bar) with gas velocity of 10 m/s. Increasing the operating conditions to 300°C temperature and 70 bar pressure will benefit overall process efficiency. Comparing the existing and suggested increased operating conditions with the Compressed Gas Association prescribed Pressure-Velocity (PV) curve, it was observed, utilized velocity was above the recommendation to minimize particle ignition and necessitates materials compatibility assessment. The assessment was performed using particle impact (PI) testing on two selected curved tubes – large curve diameter representing larger frictional path and small curve diameter representing higher impingement angle. The PI testing was carried out using mixture of metal and inert particles in similitude to particles observed in actual system. The testing also included transient and steady-state conditions to simulate startup and normal operating conditions, respectively. The research results showed higher particle ignitions for transient testing in large diameter curve tube. Larger frictional path provided increased energy input to particles to undergo ignition. Although tube wall showed a heat affected zone of ~100µm due to ignited particles depositing as slag, the tubes were not kindled. The research results have uncovered new understanding of materials response in PI testing and would have a significant influence in operating oxygen systems safely at elevated temperature and pressure.

Further reading: Learn about particle impact testing in curved tubing

Quantitative Ignition Probability Analysis of Particle Impact in an Oxygen Control Valve

Authors: Elliot T. Forsyth, Nic Linley, Gwenael Chiffoleau, Brent Houser, Barry Newton

Over the years, various methods have been developed and presented for analyzing fire risk in oxygen systems and components. These methods generally consider the system or component’s maximum operating conditions, materials of construction, and operational function to formally rate the flammability of oxygen-wetted materials (on a binary scale situationally flammable or nonflammable), and the ignition probability and ignition consequence (reaction effects) on a multi-tiered severity scale (number and letter grades). Although these methods rely heavily on flammability and ignition test data for materials in oxygen, as well as other factors, the analysis result is overall qualitative in nature. This qualitative approach has proven useful for analyzing the general risk of fire in oxygen systems and components; however it falls short of predicting the quantitative ignition probability based on known factors, or characteristic elements. Applying established quantitative probability analysis (QPA) techniques to oxygen fire hazards, specifically to ignition probability, can provide significantly more information to technical personnel who make critical design decisions, especially related to the materials of construction within a component. WHA International, Inc. (WHA) has developed a methodology for analyzing the quantitative ignition probability of particle impact ignition in an oxygen control valve. The quantitative ignition probability analysis (QIPA) approach used and factors considered are presented along with the results of the QIPA.

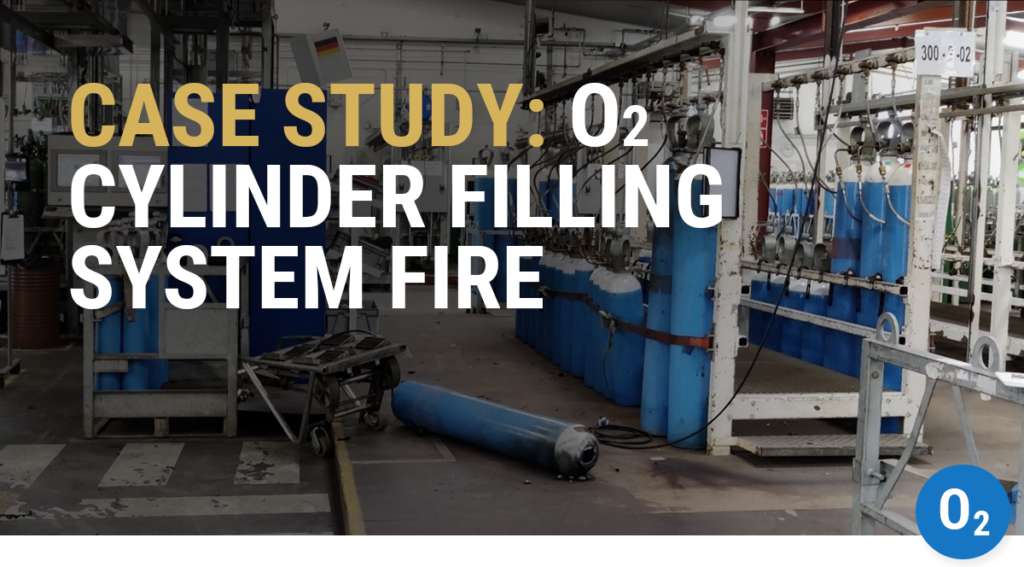

Oxygen Cylinder Fire During Filling

Authors: Bradley S. Forsyth, Brian C. Anderson

The authors investigated a fire that occurred in an industrial oxygen cylinder filling system resulting in ignition and combustion of a steel compressed gas cylinder. The incident occurred when the operator found the subject cylinder valve closed (cylinder had not been filled) and subsequently opened the cylinder valve with a high-pressure differential between the manifold and the cylinder.

Based on the physical evidence, a seal in the residual pressure valve (RPV) installed at the cylinder valve outlet was the most probable fire origin and first material ignited. Other observed damage to the cylinder valve and cylinder were consistent with a kindling chain developing from ignition of the RPV seal during high gas flow into the cylinder from the filling manifold.

Significant combustion damage was observed to the valve threaded connection and associated region of the cylinder. Notably, a sintered filter element installed at the cylinder valve stem visually appeared to be constructed of copper with a sintered bronze element. However, analysis of the filter indicated the threaded portion was a steel alloy (copper-coated). The flammability of this component contributed to propagating the fire to the cylinder.

Observations and evidence indicated combustion occurred internal to the GOX cylinder until the pressure containment was breached when the structure in the cylinder neck area failed due to thinning and heating. Observed damage to the fill system flex hose and fill adapter fitting were consistent with external damage after breach of the cylinder.

Several operational and design issues contributed to the ignition and fire event.

Share this entry

Related Articles

Battery Safety Insights with Nic Linley, Electrical Engineer

Battery technology continues to evolve rapidly in the 21st Century, powering an expanding array of devices and…

Oxygen Cylinder Filling System Fire Case Study

Oxygen cylinders and pressure systems quietly hold enormous amounts of energy. When things go wrong, the results…

WHA Presents O2 Safety Papers at 2024 ASTM G04 Symposium

In October 2024, Gwenael Chiffoleau, Nic Linley, and Brent Houser traveled to Prague for the 16th ASTM…

Request an expert

consultation

Contact us to request a free consultation with an experienced engineer who can help you better understand your needs and our solutions.