Your Subject Matter Experts

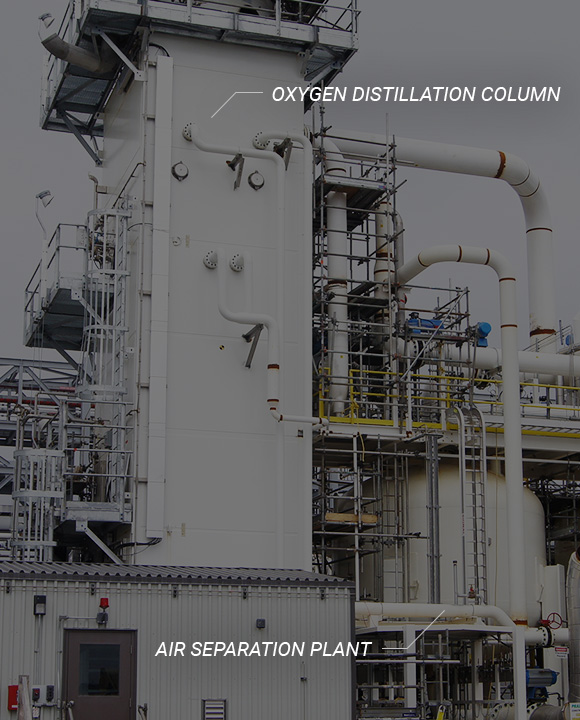

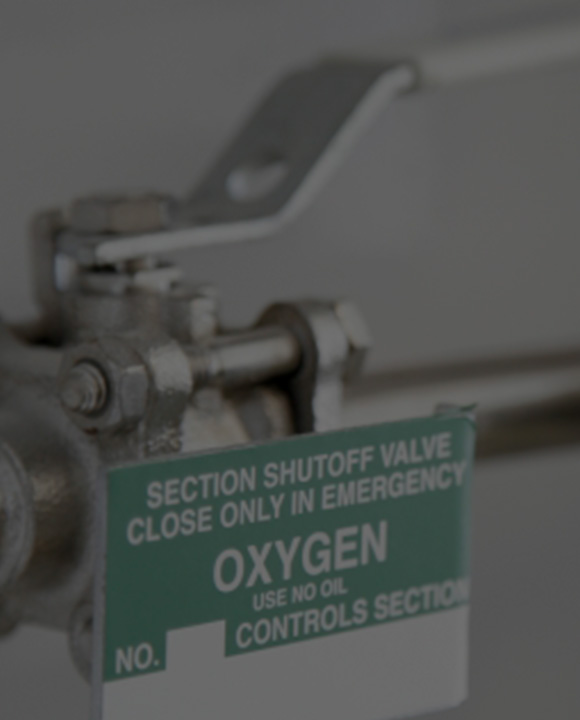

Hazardous fluids like oxygen and hydrogen can be extremely dangerous. WHA leverages its experience in analyzing fires, testing materials and equipment, and writing technical standards and publications to develop specialized tools and methods that are proven to mitigate the risk of fire and protect people and equipment.

We don’t just identify risks but are dedicated to finding solutions and providing recommendations on how to make your systems and components safer. As part of the solution, we often provide inspection and consulting services and customized technical training for your staff.

Oxygen Fire Risk Analysis

WHA’s formal Oxygen Fire Risk Analysis (OFRA) tool is the predominant method used to analyze oxygen fire risks in both systems and components for industries worldwide. WHA maintains a unique oxygen compatibility materials database to support our analyses, so our recommendations are grounded in real test data, not just expert opinion.

We offer fire risk analyses at several different levels, ranging from a basic Level 1 Oxygen Hazard Consult (OHC) to a formal Level 3 OFRA with a comprehensive technical report. Your customized solutions may also include specialized services like Failure Mode and Effects Analysis (FMEA), Materials Flammability Analysis (MFA), and an Oxygen Cleaning Process Review (OCPR). Other specialty testing services, such as oxygen compatibility testing, are available when additional data is required.

Hydrogen Combustion Risk Analysis

Based on our experience and knowledge of established methodologies, we’ve developed a Hydrogen Combustion Risk Analysis (HCRA) method customized to the unique hazards of hydrogen today.

HCRA services are also available at multiple levels of complexity for materials, components, and systems using hydrogen.

Safety Consulting

WHA advances safety around the globe through system inspection and safety consulting for oxygen, hydrogen, and other hazardous fluids. Our experienced engineers regularly review systems, components, and processes, both in-person and remotely. We often package safety inspection and consulting with technical training solutions.

Compliance Auditing

Compliance audits include a system inspection performed to specific industry standards. Common oxygen system and component design standards include:

- ASTM G88

- CGA G-4.4/EIGA 13-12

- ASTM G93

- CGA G4.14/EIGA 200/17

- EASA CS-25

- and others

Common hydrogen system standards include:

- NFPA 2

- ISO TC 197

- and others

Hazardous Fluid Safety

WHA uses many of its industry-leading analysis tools and methods to analyze hazardous fluids. Many of these fluids pose their own unique hazards in addition to more general pressure system hazards, including pressure vessel failures, explosions, and reactions. These fluids can include:

- Oxygen

- Non-oxygen oxidizers (nitrous oxide (N2O), nitrogen trifluoride (NF3), fluorine, ozone, compressed air, etc.)

- Hydrogen and hydrogen mixtures

- Fuel gases (acetylene, propane, natural gas, etc.)

- Compressed or liquid “inerts” (nitrogen, argon, helium, etc.)