Ignition of materials is often part of the critical kindling chain in promoting oxygen component burnout. WHA’s materials tests evaluate compatibility with oxygen according to the predominant standards. The results primarily help inform manufacturers designing components for use in oxygen systems. International standards for compatibility are defined by organizations, including ASTM and ISO.

Lubricants and Non-Metals Compatibility Tests

Non-metals compatibility tests evaluate the ignition and flammability properties of oils, greases, plastics, rubbers, and other non-metal materials in gaseous or liquid oxygen environments. Further, these tests may be performed in other oxidizers (nitrous oxide) or at non-standard conditions (e.g. high pressure, high temperature).

- AIT – Autogenous Ignition Temperature (AIT) of Nonmetals (ASTM G72, ISO 11114:3, ISO 21010)

- HoC – Heat of Combustion (ASTM D4809)

- GFIS – Gaseous Fluid Impact Sensitivity (Oxygen Pressure Surge Test) (ASTM G74, ISO 21010)

- LOXMIS – Liquid Oxygen Mechanical Impact Testing Sensitivity (ASTM G86, ASTM D2512, ISO 21010, NASA Test 13A)

- PGOXMIS – Pressurized Gaseous Oxygen Mechanical Impact Sensitivity (ASTM G86, NASA Test 13B)

- OI – Oxygen Index (ASTM G125)

- Aging – (ASTM G114)

- HBO AIT – AIT for hyperbaric oxygen (special case in ASTM G72 (Section 8.2.3) for a low-pressure application).

- Insulation Hot Wire Test – (ISO 21010)

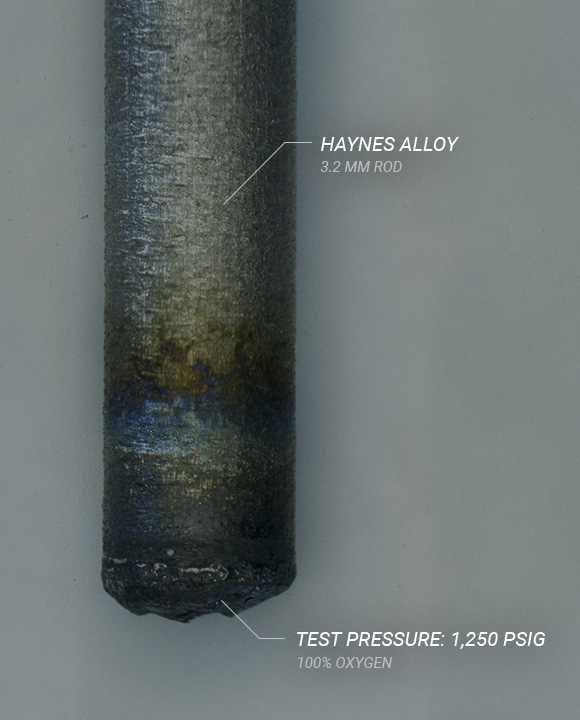

Metals Compatibility Tests

Metals can be used in a variety of different ways in oxygen systems, which may include component materials (valve bodies, internal components, etc.), tubing or piping, hard-facing materials (i.e., weld overlays and coatings), and filters. WHA’s metals compatibility tests evaluate the flammability and ignition of metals in oxygen-enriched environments.

- Promoted Combustion of Metals (ASTM G124)

- Heated Promoted Combustion of Metals (ASTM G124)

- Minimum ignition energy of metals (Custom Test)

WHA Oxygen Material Compatibility Database

WHA has archived decades of oxygen material compatibility test data in our online WHA Oxygen Material Compatibility Database. Engineers can utilize this data to support oxygen component or system design decisions or for a component or system oxygen hazard analysis.