Is your company oxygen safety compliant?

Regulatory safety compliance (or compliance to specific safety standards) is a goal that organizations worldwide aspire to achieve. But what does this look like for oxygen systems and equipment? Oxygen safety is a broad concept that many companies find confusing, and often, they look to the question of “compliance” to help gauge whether or not they are using oxygen safely. At WHA, we help companies in every industry achieve compliance to specific standards and regulations that govern the safety of their oxygen systems and equipment.

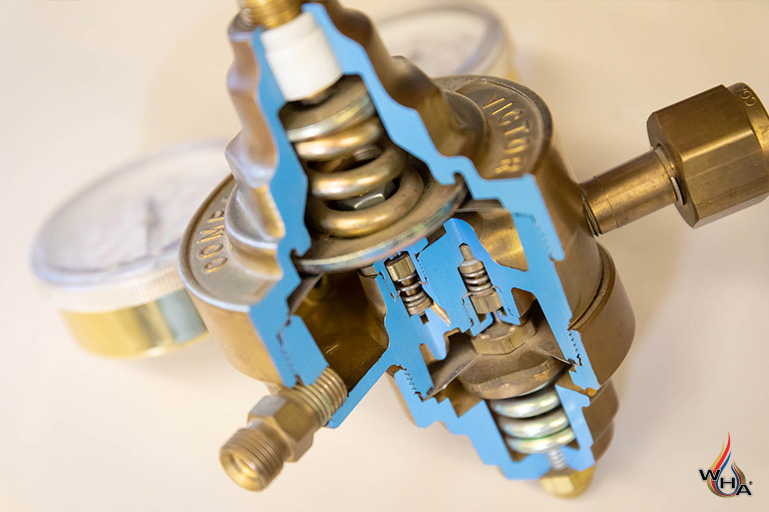

At its core, oxygen safety compliance primarily deals with reducing the risk of oxygen fires — ensuring oxygen systems and equipment have a low probability and consequence of ignition. Oxygen is a strong oxidizer, and when oxygen concentrations and pressures are increased, materials generally become more flammable and require less energy to ignite. Most of industry’s best practices that govern oxygen safety compliance — including some regulations enforced by authorities having jurisdiction — are captured in international standards that fall under three central categories:

- Design & Materials Selection: choosing the right materials and applying best design practices to create safe oxygen systems.

- Cleaning & Maintenance: using best practices to clean and maintain oxygen systems to keep them safe.

- Training: educating all oxygen users about the hazards and best practices for safe oxygen use.

Every industry that uses oxygen may have specific pathways to compliance that look a little different. This can be based on the end-use application and even geographic location. At WHA, we work with nearly every application of oxygen throughout the world, so we’re well positioned to help companies in any industry achieve compliance.

WHA can serve in a variety of roles to support oxygen safety compliance, from acting as an independent third-party auditor to partnering directly with clients to achieve compliance by demonstrating oxygen systems or equipment have a low probability and consequence of ignition. In addition, WHA can train personnel on how to analyze their own compliance (see WHA’s Level 3 and Level 4 training courses), or simply meet federal requirements by training personnel on the oxygen hazard (see Level 1 and Level 2 training courses).

The following are just a few examples of common applications of oxygen and the specific standards that govern oxygen safety compliance within that industry.

Industrial Oxygen Pipeline Systems

In industrial oxygen systems, oxygen is typically generated by air separation plants and distributed in larger-diameter industrial piping where it’s used for a variety of end applications, including steel making, metals refining, chemical processing, synthesis of gas production, etc.

Compliance concerns for industrial oxygen use are centered around system design, including materials selection, oxygen cleaning, and operations/maintenance activities. Notable standards include:

- CGA G-4.4 and EIGA IGC 13/12 (harmonized) – Oxygen Pipeline and Piping Systems

- CGA G-4.14 and EIGA IGC 200/17 (harmonized)– Design, Manufacture, Installation, Operation and Maintenance of Valves used in Liquid Oxygen and Cold Gaseous Oxygen Systems

- CGA G-4.1 and EIGA IGC 33/18 (harmonized) – Cleaning of Equipment for Oxygen Service

- ISO 21010 – Cryogenic vessels – Gas/material compatibility

- ASTM G63 – Standard Guide for Evaluating Nonmetallic Materials for Oxygen Service

- ASTM G94 – Standard Guide for Evaluating Metals for Oxygen Service

- ASTM G93 – Standard Guide for Cleanliness Levels and Cleaning Methods for Materials and Equipment Used in Oxygen-Enriched Environments

In order to show compliance for industrial oxygen systems, WHA engineers can perform oxygen fire risk analyses on systems and components or demonstrate materials compatibility through testing. Tests can include materials and component testing to ISO, CGA, ASTM, EN and other standards, as well as testing consistent with BAM, the German Government Federal Testing Laboratory. WHA can also clean oxygen equipment to comply with the highest levels of cleanliness required for industrial oxygen equipment or perform oxygen clean verification on pre-cleaned equipment.

Commercial Aircraft Oxygen Systems

In commercial aircraft, oxygen is available as a breathing gas, providing emergency life support. Compliance in aircraft is two-fold, first addressing the physiological life support needs of those on board, and second, addressing oxygen fire hazards.

In the first case, systems and devices must be able to deliver and maintain a sufficient flow of oxygen to support the respiratory needs of the pilot, crew members, and passengers in an emergency situation where the cabin loses pressure. Regulatory standards require aircraft oxygen equipment manufacturers to demonstrate that their life support equipment can meet these oxygen flow requirements.

In the second case (and more specifically to WHA’s expertise), aircraft oxygen systems compliance addresses fire risks. These systems must be shown to have a low risk of ignition and external fire, either from direct use of the equipment in an emergency situation or from a failure event such as a leak.

Many oxygen safety standards for commercial aircraft are provided by SAE Committee A-10 and are governed by either the Federal Aviation Administration (FAA) in the US or the European Aviation Safety Agency (EASA) in Europe. Notable compliance standards include:

- SAE standard AIR-825/13– Guide for Evaluating Combustion Hazards in Aircraft Oxygen Systems

- EASA CS-25 – Certification Specification for Large Aeroplanes

- SAE ARP 1176– Oxygen System and Component Cleaning and Packaging

In order to show compliance for commercial aircraft oxygen systems, WHA consultants can perform oxygen fire risk analyses on systems and component within aircraft, or they can work with clients to demonstrate a low ignition probability and consequence through oxygen standard testing. WHA can also clean oxygen equipment to comply with the highest levels of cleanliness required for aircraft oxygen. Finally, WHA engineers have even served in the unique roll of a Certification Engineer (CE) for clients to certify that oxygen systems comply with the EASA Airworthiness Code items in CS-25.

Healthcare & Medical Oxygen

In medical oxygen applications, oxygen is used as a breathing gas for emergency applications, during surgery, or for respiratory therapy. It is usually transported in portable compressed oxygen cylinders and delivered through regulators and small high-pressure tubing. Because this healthcare equipment is used in such close proximity to people, fire risk is of utmost concern. Applications like hyperbaric oxygen (HBO2) chambers can also present complex challenges in mitigating fire hazards.

Notable healthcare oxygen safety compliance standards include:

- NFPA 53–Recommended Practice on Materials, Equipment, and Systems Used in Oxygen-Enriched Atmospheres

- NFPA 99 – Health Care Facilities Code

- ASTM G72 – Standard Test Method for Autogenous Ignition Temperature of Liquids and Solids in a High-Pressure Oxygen-Enriched Environment

- ISO 15001 – Anesthetic and respiratory equipment — Compatibility with oxygen

- IEC 60601-1 – Requirements for medical electrical equipment and medical electrical systems used in the home healthcare environment

- NFPA 77 – Recommended Practice on Static Electricity

In order to help medical oxygen equipment manufacturers and end-users show oxygen safety compliance, WHA engineers can perform oxygen fire risk analyses on systems and components, demonstrate compatibility through testing of both materials and components to ISO, ASTM, CGA, EN, and other standards, as well as perform what has become known as BAM testing, consistent with ISO 21010, material testing. WHA can also clean oxygen equipment to comply with the highest levels of cleanliness required for medical oxygen equipment or perform oxygen clean verification on pre-cleaned equipment.

Required Safety Training

For any industry, WHA provides a variety of oxygen safety training courses that can function to meet federal requirements for hazard communication (see Level 1 and Level 2 training courses). In the United States, governing bodies like the Occupational Safety and Health Administration (OSHA) mandate that companies provide employees with effective information and training on hazardous materials. Concentrated oxygen is considered a hazardous material, and thus, safety training on oxygen hazards is compulsory for any company that uses oxygen.

- OSHA CFR1910.1200 – Hazard Communication

Additionally, WHA can provide advanced-level training to educate personnel on how to analyze their own compliance. These courses can help familiarize your staff with relevant industry standards that govern oxygen system and component design (see WHA’s Level 3 training) and also provide instruction on performing Oxygen Fire Risk Analysis (OFRA) (see WHA Level 4 training). Training can also include add-on modules on topics like oxygen cleaning so your personnel can understand compliance in both facility requirements as well as best practices for oxygen cleaning processes.

We’re here to help

The world of oxygen safety compliance can be complicated, but WHA exists to simplify oxygen safety, helping companies navigate, understand, and implement standards and best practices to meet compliance requirements and keep employees and systems safe.

If you’d like to learn more about compliance for a specific industry or application, please contact us to let us know. We’ll be taking a closer look at compliance in the next few months and will try to address as many questions as we can.

Share this entry

Related Articles

Nonmetals Oxygen Compatibility Requirements: Guide to CGA/EIGA Compliance

The Compressed Gas Association (CGA) and European Industrial Gases Association (EIGA) have harmonized key documents providing guidance…

WHA Launches Oxygen Equipment Supplier Certification Program

Ignition and combustion hazards are present in almost all oxygen and oxygen-enriched systems, and catastrophic fires have…

Oxygen Cleaning Service Team Receives Vendor Award

WHA’s oxygen cleaning service team recently received recognition from its client, Trace-A-Matic, for excellent service in a…

Request an expert

consultation

Contact us to request a free consultation with an experienced engineer who can help you better understand your needs and our solutions.