Top Industrial Uses of Hydrogen, and the Need for Industrial Hydrogen Safety

Highlights

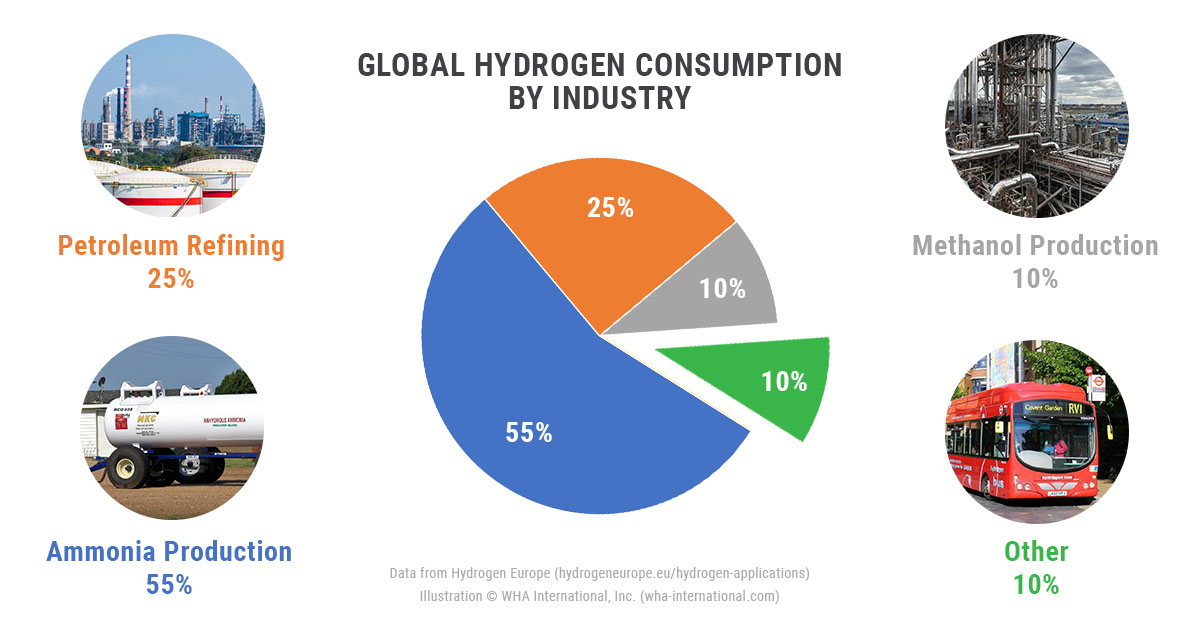

- Hydrogen has emerged as a promising clean fuel, but alternative energy represents just a small sliver of its overall application.

- The two of the largest uses of hydrogen worldwide are ammonia production (55%), and petroleum refinement (25%).

- WHA International offers safety services for the growing hydrogen industry, for both industrial applications and emerging technologies.

Hydrogen is quickly becoming a global contender for alternative energy, but these applications actually account for less than 10% of global hydrogen consumption.[i]

The lion’s share of hydrogen usage actually goes to industrial applications. Ammonia production, for instance, represents 55% of hydrogen usage worldwide!

As the hydrogen economy grows, the world is rethinking the way it works with hydrogen.

In this article, we will look at the historic leaders of global hydrogen consumption, as well as the newer industrial contenders for hydrogen technology and innovation.

Historical Hydrogen Industrial Uses

For decades, hydrogen has been used primarily by the chemical and refining industries. Industries include:

- Agricultural and Chemical Industry:

Hydrogen is a fundamental raw material needed to produce ammonia (NH3), also known as azane. Ammonia is an important part of fertilizers used in agricultural industries around the world. Ammonia can also be used as an affordable, environmentally-friendly refrigerant (R-717). - Petroleum Refining Industry

Hydrogen is also commonly used in a process called “hydrocracking” to create petroleum products, including gasoline and diesel. (Hydrocracking is the process in which hydrocarbon molecules are broken down into smaller molecules.) In the petroleum industry, hydrogen is also used to remove contaminants like sulfur and to create methanol (CH3OH).

Other Common Industrial Uses for Hydrogen

Hydrogen also has a long history of use in several other industries. These include:

Food

Hydrogen is used to turn unsaturated fats into saturated oils and fats, including hydrogenated vegetable oils like margarine and butter spreads.

Metalworking

Hydrogen is used in metalworking for processes like metal alloying, where it’s introduced to molten metals to enhance properties like strength and corrosion resistance.

Welding

Hydrogen is used in welding primarily in atomic hydrogen welding (AHW). In this process, hydrogen is split into atoms through an electric arc. These atoms combine to create a flame that melts metals.

Flat Glass Production

Flat glass is a type of glass that’s often used for windows and glass doors. In its production, hydrogen and nitrogen are used to prevent oxidation and defects during manufacturing.

Electronics Manufacturing

In electronics manufacturing, hydrogen is an efficient reducing and etching agent. It’s used to create semiconductors, LEDs, displays, photovoltaic segments, and other electronics.

Medical

In the medical industry, hydrogen is used to create hydrogen peroxide (H2O2), a commonly used antiseptic. Recently, hydrogen has also been studied as a therapeutic gas for a number of different diseases.

Hydrogen Energy Industry Applications

Newly commercialized applications of hydrogen, like fuel cells, are opening all kinds of new opportunities in transportation and other energy-related industries. In some applications, hydrogen is used as an alternative combustible fuel.

Energy applications include:

- Space exploration and aviation

- Global logistics

- Public transportation

- Personal transportation

- Power generation and backup power generation

Hydrogen fuel cells play a large role in this transition to renewable energy.

WHA: Helping Keep Industry Safe Around Hydrogen

It’s exciting to see new applications for hydrogen emerge in industry. But as the hydrogen industry grows, so do the risks. Many new applications of hydrogen require conditions that have rarely been seen on a large commercial scale. Transportation fuel cell systems, for instance, store hydrogen at astronomically high pressures, and other applications operate with extreme cryogenic temperatures. To avoid tragic accidents, hydrogen must be handled with proper expertise and according to industry standards.

Since 1987, WHA has been investigating hydrogen incidents and using lessons learned to help industry defend against hydrogen fires and explosions. WHA experts have even helped create many of the international hydrogen standards that exist today.

Many of our engineers come directly from NASA or the National Renewable Energy Laboratory (NREL). Our consultants have played pivotal roles in the technology development and safe use of hydrogen and are uniquely equipped to address industry concerns in hydrogen safety.

To keep industry safe from the hazards of hydrogen, WHA offers hazard analysis, custom testing, and other specialized safety services.

Wherever hydrogen is used, it is especially important that personnel receive proper hazardous materials training. In fact, OSHA requires it. WHA helps clients meet and exceed this requirement by providing multiple levels of hydrogen safety training, all taught by WHA’s expert-level instructors.

WHA International is ready to support industry’s hydrogen safety needs. No matter the industry or final application, hydrogen safety considerations will allow us to make true progress toward more efficient and cleaner means of production.

[i] https://hydrogeneurope.eu/hydrogen-applications

Originally published September 20th, 2020.

Share this entry

Related Articles

Nonmetals Oxygen Compatibility Requirements: Guide to CGA/EIGA Compliance

The Compressed Gas Association (CGA) and European Industrial Gases Association (EIGA) have harmonized key documents providing guidance…

WHA Launches Oxygen Equipment Supplier Certification Program

Ignition and combustion hazards are present in almost all oxygen and oxygen-enriched systems, and catastrophic fires have…

Hydrogen Embrittlement: Hazards and Mitigation Strategies

Hydrogen embrittlement (HE) is a critical concern in industries utilizing hydrogen, posing significant safety concerns if not…

Request an expert

consultation

Contact us to request a free consultation with an experienced engineer who can help you better understand your needs and our solutions.