Hydrogen Embrittlement: Hazards and Mitigation Strategies

Highlights

- Exposure to hydrogen can compromise the integrity of certain metals.

- Hydrogen embrittlement can cause hydrogen leaks and subsequent fires.

- Proper material selection and design measures can reduce and mitigate risks associated with hydrogen embrittlement.

Hydrogen embrittlement (HE) is a critical concern in industries utilizing hydrogen, posing significant safety concerns if not adequately addressed. Incompatible materials can lead to leaks and hydrogen fires or explosions. In this article, we’ll present a high-level overview of embrittlement, focusing on hazards and mitigation strategies.

What is Hydrogen Embrittlement?

Hydrogen embrittlement is a phenomenon where metals become brittle and susceptible to cracking with exposure to pressurized hydrogen.

Although a highly complex and nuanced topic, the gist is this: In pressurized hydrogen environments, hydrogen molecules (H2) can dissociate into monoatomic hydrogen at the surface of the metal and migrate into the bulk metal.

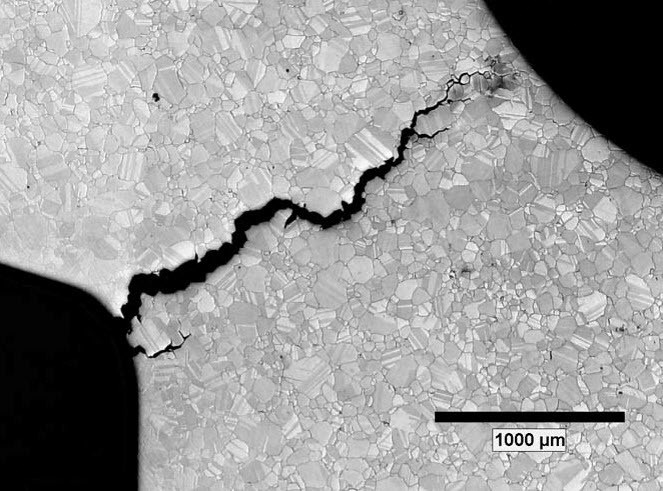

Hydrogen atoms are incredibly small — the smallest on the periodic table of elements. Once in the bulk metal matrix, hydrogen degrades the material strength by causing discontinuities at grain boundaries, inclusions, and dislocations, recombining into molecular hydrogen in voids, assisting with crack growth, and other internal effects. The result is a reduction in the ductility and strength of the material.

Although some metals are more susceptible than others, the impact of hydrogen on metals is also a function of exposure environment (pressure, temperature, and gas composition) as well as stress. Without the metal being in a stress state, environmental embrittlement will not propagate cracks, even if the metal is embrittled.

Hazards of Hydrogen Embrittlement

Embrittlement poses a severe risk in industries utilizing hydrogen, such as energy, manufacturing, transportation, and aerospace. When a metal’s integrity is compromised it can lead to leaks and combustible mixtures, which can result in a fire or explosion.

- Material Integrity Compromise: Hydrogen embrittlement compromises the integrity of metals, potentially leading to catastrophic failures. This is a critical concern since the reliability of components is paramount to hydrogen combustion safety.

- Leakage Risks: Incompatible materials can develop cracks due to hydrogen embrittlement, resulting in the potential for leaks. Hydrogen is highly flammable when mixed with oxygen; even small leaks can pose significant safety risks.

- Hydrogen Fires: Where hydrogen leaks and combines with air or oxygen, it can create an easily ignitable mixture which can lead to fires or explosions. These can be highly destructive and pose severe risks to personnel, equipment, and facilities.

Case Example: Hydrogen Bus Refueling Station Failure

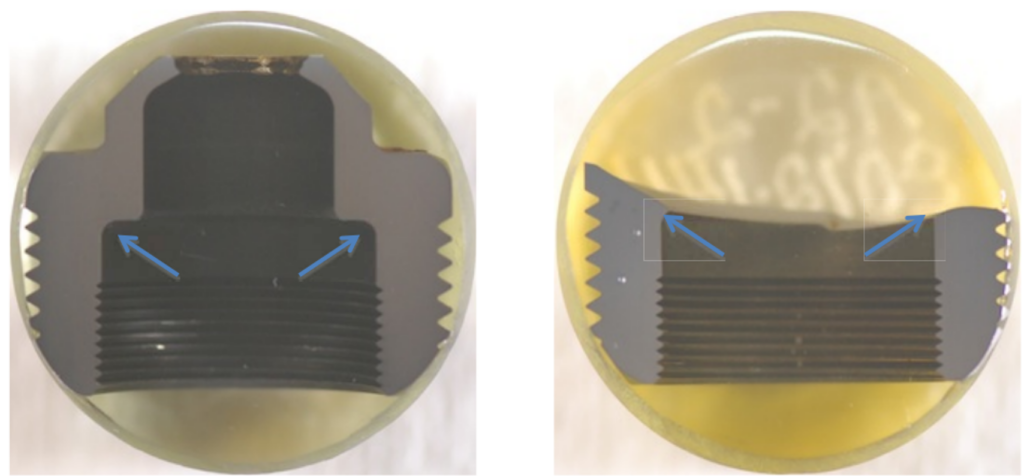

In 2012, hydrogen embrittlement led to a pressure relief valve failure at the AC Transit Facility in Emeryville, CA, a refueling station for hydrogen-powered buses.

Sandia National Laboratory (Livermore, CA) conducted an extensive metallurgical analysis of the failed valve. It concluded that incompatible materials (440C Martensitic stainless steel) and deviations in the manufacturing process led to hydrogen embrittlement and, ultimately, the failure of a PRD nozzle.

Fortunately, backup venting systems functioned properly, and no one was harmed in the subsequent hydrogen release, but the incident caused the precautionary evacuation of a one-block radius. Like many hydrogen failures, it caused understandable concern and damaged the public perception of this emerging technology.

Mitigating Hydrogen Embrittlement Risks

Over more than 35 years, WHA International has investigated fires, explosions, and incidents involving hydrogen. Hydrogen embrittlement is one of the hazards evaluated in WHA’s Hydrogen Combustion Risk Analysis (HCRA) services. This systematic process aims to identify potential risks in hydrogen systems and recommend design changes to enhance safety. Key mitigation strategies include:

- Material compatibility assessment: Conduct thorough assessments to identify metals susceptible to hydrogen embrittlement. WHA recommends the use of test data to assess a metals’ vulnerability to embrittlement. Implementing compatible materials is crucial for preventing embrittlement-related failures as well as leaks.

- Design modifications: Implement design modifications to mitigate the risks associated with hydrogen embrittlement. This may include changes to materials, increasing the factor of safety, making adjustments to the exposure environment, and suggesting component and system design modifications.

- Reducing the probability of ignition: Identify potential ignition sources in and around a hydrogen system. Since flammable mixtures of hydrogen and air or oxygen need very little energy to ignite, completely eliminating the ignition risk is not always possible. Therefore, mitigation strategies are focused on reducing the probability of ignition and the likelihood of hydrogen mixing with an oxidizer to create flammable mixtures.

- Reducing the consequence of ignition: Design best practices also include fail-safe measures like automated shutoff systems, venting systems, ventilation, and barriers to protect personnel and nearby equipment in case of ignition.

Further reading: learn more about WHA’s Hydrogen Fire Risk Management Philosophy.

Protect your personnel and equipment around hydrogen

Hydrogen embrittlement is a serious concern that demands attention in industries utilizing hydrogen. By understanding the hazards associated with incompatible materials and implementing mitigation strategies, companies can enhance the safety of their hydrogen systems.

While this article provides only a general introduction to the topic, our Level 3: H2 Design and Level 4: H2 Analyze courses include a more in-depth discussion on hydrogen embrittlement, including:

- Overview of hydrogen embrittlement (HE)

- Types and characteristics of HE

- General compatibility of:

- Aluminum alloys

- Nickel alloys

- Austenitic stainless steels

- Ferritic steels

- HE evaluation by test data

- Effect of HE on weld joints

- Effectiveness of surface barriers and coatings

- Effect of temperature and pressure

- Effect of purity

- How to reduce the impact of hydrogen embrittlement by

- Selecting compatible materials

- Reducing stress

- Increase factor of safety

- Changing environment

- HE evaluation with design based testing

WHA International’s Hydrogen Combustion Risk Analysis (HCRA) services also play a crucial role in identifying and addressing HE risks, ensuring the reliable and safe operation of hydrogen-related processes. Contact us to inquire about HCRA services.

Share this entry

Related Articles

Hydrogen Embrittlement: Hazards and Mitigation Strategies

Hydrogen embrittlement (HE) is a critical concern in industries utilizing hydrogen, posing significant safety concerns if not…

Advancing Large-Scale Electrolyzer Safety

Electrolyzer safety is becoming increasingly important as the industry undergoes significant change to meet the growing demand…

Will hydrogen power the future of Aerospace?

As the world moves towards clean energy technologies, finding alternatives to traditional fuels is particularly challenging in…

Request an expert

consultation

Contact us to request a free consultation with an experienced engineer who can help you better understand your needs and our solutions.