WHA Involvement in ASTM protects oxygen industry

Have you ever wondered how materials used in oxygen systems are tested to help judge their compatibility? How oxygen systems are designed to prevent ignition? And what about oxygen cleaning? Exactly how clean is “oxygen clean?”

These are all questions WHA’s clients face daily, and because of WHA’s long history with ASTM International, these questions can be readily answered. This unique relationship between WHA and ASTM helps industry stay safe around oxygen.

Since 1975, the non-profit organization ASTM International (originally formed as the American Society of Testing and Materials) has played a significant role in the safe design and use of oxygen and oxygen systems. ASTM Committee G04 is a committee within ASTM that focuses on understanding oxygen fire hazards and promoting oxygen safety. They carry out their mission in three main ways:

- Generate test standards that evaluate the ignition and combustion characteristics of materials and components in oxygen.

- Produce standards on recommended practices for the safe use of oxygen.

- Promote educational and research opportunities to increase knowledge of oxygen hazards and safe use strategies.

Today, the organization continues to be powered by a group of dedicated technical volunteers, representing a variety of industries that use oxygen. For over three decades, WHA engineers have provided much of the key leadership in ASTM’s work with oxygen.

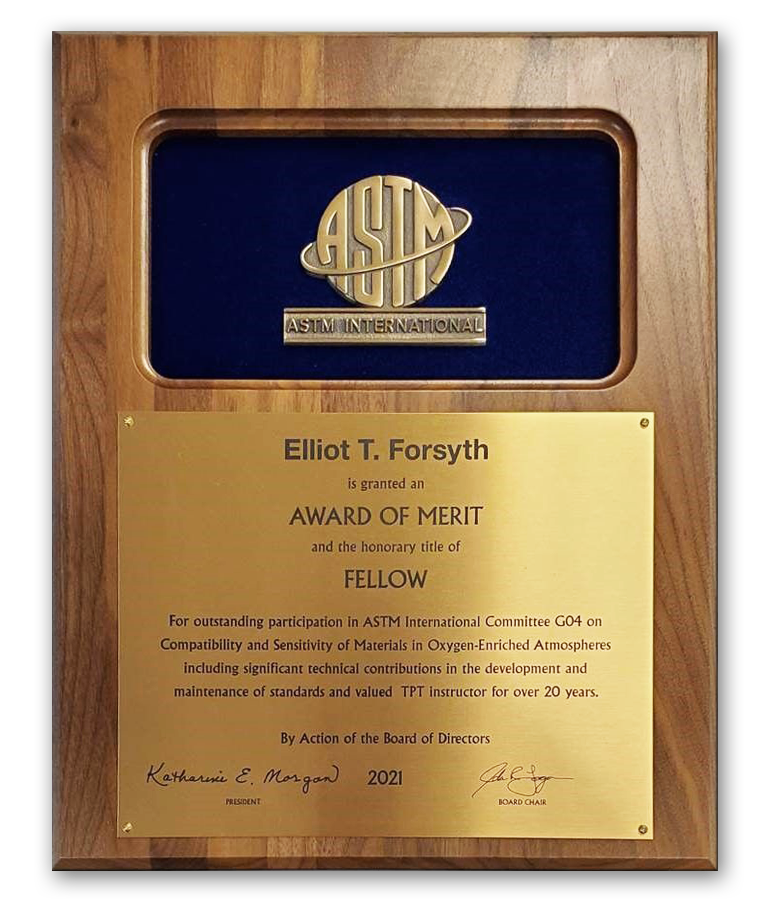

WHA is proud to announce that in April, WHA Engineer and Chief Strategy Officer Elliot Forsyth received ASTM’s Award of Merit, the highest society award granted to an individual member for distinguished service and outstanding participation in ASTM International committee activities. Recipients of this award also receive the honorary title of ASTM Fellow. This award recognizes Elliot’s 25 years of volunteer service and dedication to protecting industries around the world against oxygen fires.

We spoke with Elliot to learn more about how WHA’s history with ASTM has impacted the oxygen industry.

ASTM Committee G04

In response to a growing need for industry resources on oxygen safety, ASTM first established Committee G04 on Compatibility and Sensitivity of Materials in Oxygen Enriched Atmospheres in 1975. Today, the committee has jurisdiction over 22 standard tests, guides, and practices. The group is organized into three subcommittees: Test Methods, Recommended Practices, and an Executive Subcommittee.

ASTM is set apart by its application of data-driven science. “ASTM is the only international standards organization I know of that is developing test methods and directly applying test data to help guide industry in the safe use of oxygen,” says Elliot Forsyth. “They provide resources so that any company involved the storage, distribution, or use of oxygen can both understand the hazard and implement strategies to reduce the fire risk.”

ASTM is further distinguished in that its standards require full consensus. “Committees require 100% approval from all voters for a standard to pass. If there is even one person who votes ‘negative,’ that stops the process from going forward until the concern is resolved,” explains Elliot. “This means that industries can confidently rely on ASTM to provide fully-agreed upon technical content and information in their standards.”

WHA’s Close Ties with ASTM International

ASTM’s philosophy is closely aligned with WHA International, which also prides itself as a data-driven organization. Since its inception, WHA has served as the link between government and industry, bringing cutting edge oxygen safety science from NASA to gas producers, equipment manufacturers, and end users. This effort has always been aided by close partnership with ASTM.

“One of WHA’s most notable contributions was our work on the compression heating standard on medical oxygen regulators,” adds Elliot. Following a disturbing rise in oxygen regulator fires in the 1990s, WHA provided significant failure analysis, oxygen testing, and hazard analysis work to develop a new promoted ignition test standard which helps component designers qualify materials for use in high pressure oxygen regulators.

WHA Involvement in ASTM G04

Over the years, WHA engineers have provided key leadership and subject matter expertise to ASTM Committee G04 and its many oxygen standards.

- Barry Newton, PhD (WHA’s CEO) has the longest history of WHA service to the ASTM G04 Committee, dating back to the days he worked at NASA White Sands Test Facility (WSTF), nearby in Las Cruces, New Mexico. Barry’s expertise in materials compatibility for both gaseous oxygen (GOX) and liquid oxygen (LOX) led him to become a co-developer of both ASTM and NASA technical training courses on oxygen safety. After he took a position at WHA in 1989 (then known as Wendell Hull and Associates, Inc.), he continued to share his strong expertise in materials and fire science with ASTM. Since then, he has held leadership roles on the Executive Committee, the Officer Nomination Subcommittee, and the Subcommittee for Statistics and Data Handling. He was responsible for ASTM standards G72 (AIT Autogenous Ignition Temperatures), G74 (Adiabatic Compression), and G145 (Fire Failure Analysis). He was named an ASTM Fellow in 2001.

- Elliot Forsyth, PE also began his career at NASA WSTF where he became involved with ASTM G04. He had a strong background in the compatibility of materials for NASA oxygen applications, and once he came to WHA, he began applying his experience with oxygen hazard analysis, cleaning, and system design to industry’s oxygen needs. As co-developer of ASTM and NASA technical training courses on oxygen safety, Elliot developed WHA’s now world-renowned technical training programs. Elliot recently completed his tenure as the chair of the G04 Committee, and prior to that was vice chair and chair of the G04 Practices Subcommittee. He became an ASTM Fellow in 2021.

- Gwenael Chiffoleau, PhD (WHA’s Chief Technical Officer) began volunteering for ASTM G04 Committee during his doctoral thesis work at the University of Queensland in Brisbane, Australia, with his PhD professor Dr Ted Steinberg (who also consults for WHA International, Inc.). Gwenael’s area of study involved metals combustion in oxygen, based on the ASTM G124 test standard, and his research contributed significant data that helped develop the standard into what it is today. Gwenael continued to serve with ASTM after coming to WHA and has held positions of G04’s Practices Subcommittee Chair and is now serving on G04’s Executive Subcommittee. Gwenael also offers his expertise to ASTM and WHA technical training programs on oxygen safety.

- Brad Forsyth worked for 10 years at NASA WSTF performing tests on materials and equipment, including spacecraft oxygen system components and materials. He began working with ASTM after joining WHA in 2010, bringing his expertise with test methods, materials compatibility, and forensic engineering. He chaired the task group that rewrote the cleaning standard ASTM G93, and has since been elected as the chairman for G04 Practices Subcommittee and sits on the Executive Subcommittee as well.

- Harold Beeson, PhD joined WHA in 2019 after retiring from NASA where he served as a PhD chemist and NASA Chief at WSTF, and he also has a long history with ASTM. Harold was an active member of G04 during his time at NASA, heavily involved in the development of ASTM’s oxygen cleaning standards as well as instructing technical training. Harold also has the notable achievement of being chief editor of ASTM’s Manual 36, Safe Use of Oxygen and Oxygen Systems, one of ASTM G04’s most widely published documents on oxygen safety. The original text from Manual 36 is based upon NASA’s Safety Standard on Oxygen.

Multiple other WHA team members have been involved in various ASTM committees, task groups, and projects, including Greg Odom who was heavily involved in development of compression heating test standards, Joe Whitehead who has contributed to standards for GOX and LOX mechanical impact testing, and Nic Linley who has helped the committee sort through statistical analysis of data.

The late Jack Stradling was also one of the founding members of ASTM G04 under NASA, and he continued to serve throughout his time at WHA where he received the ASTM award of merit.

WHA engineer Joe Whitehead demonstrates a LOX mechanical impact test for a technical training course at WHA. He was closely involved with ASTM in the development of this oxygen test standard.

The Future of Oxygen Safety

“Now, we’re passing the baton to younger engineers, allowing them opportunities to get involved in standards development and interfacing with oxygen experts from all industries,” shares Elliot. Some, like WHA engineer Brad Forsyth have come onboard under the Emerging Professionals program for young enterprising engineers who want to get involved.

“It’s especially important for WHA engineers to continue their close relationship with ASTM,” explains Elliot. “Because we help write these standards, we can bring that intimate understanding to help equip and protect our clients in industry. At WHA, we’re also performing research and generating new test data almost every day. We bring that data and knowledge back to ASTM to continue to further the science of oxygen safety.”

Share this entry

Related Articles

Nonmetals Oxygen Compatibility Requirements: Guide to CGA/EIGA Compliance

The Compressed Gas Association (CGA) and European Industrial Gases Association (EIGA) have harmonized key documents providing guidance…

WHA Launches Oxygen Equipment Supplier Certification Program

Ignition and combustion hazards are present in almost all oxygen and oxygen-enriched systems, and catastrophic fires have…

Oxygen Cleaning Service Team Receives Vendor Award

WHA’s oxygen cleaning service team recently received recognition from its client, Trace-A-Matic, for excellent service in a…

Request an expert

consultation

Contact us to request a free consultation with an experienced engineer who can help you better understand your needs and our solutions.