Watch a Liquid Oxygen Mechanical Impact Sensitivity Test

The Problem: Mechanical Impact Can Ignite Materials in Oxygen

Anyone who has attended WHA’s oxygen safety training will be quick to tell you that materials become more flammable and easier to ignite in oxygen. They would also affirm that ignition mechanisms for metals or nonmetals in oxygen components and systems come from a variety of energy forms. For example, WHA has investigated many fires in oxygen systems that started due to mechanical energy caused by impacts, vibration, or friction.

As you can imagine, this issue is of utmost importance for engineers designing oxygen systems and components. All materials must be analyzed and chosen carefully in order to reduce the risk of ignition.

Today, we’re taking a closer look at one important question often asked in design: how much impact energy is necessary to ignite a particular nonmetallic material in oxygen?

The Solution: Standard Testing Reveals Ignition Potential

Mechanical Impact Sensitivity (MIS) testing is just one of many standard tests that WHA engineers perform to help qualify materials for use in oxygen systems and components. It follows the testing standards outlined primarily in ASTM G86, ASTM D2512, and ISO 21010.

WHA tests the impact sensitivity of materials in both liquid oxygen (LOX) and gaseous oxygen (GOX) at ambient pressure and in pressurized environments. Oxygen makes up only 21% of the air we breathe, but in liquid form, LOX is almost 900 times denser than GOX. As a result, many materials are more reactive in LOX than GOX, and much more reactive than in air.

Test Method: Liquid Oxygen Mechanical Impact Sensitivity

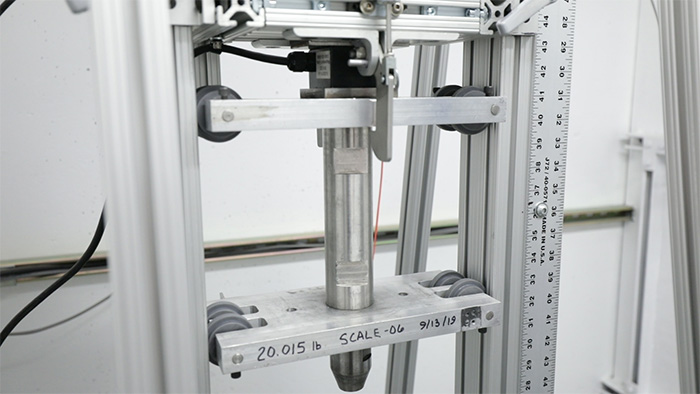

The Liquid Oxygen Mechanical Impact Sensitivity (LOXMIS) test is simple in principal: first, a carefully measured mass is suspended a certain distance above the test sample using a special near-free-fall apparatus. This means that test engineers can easily calculate the potential energy imparted based on mass, distance, and the acceleration of gravity.

Next, a small material sample is prepared and placed in a sample cup. After chilling in LOX, the cup is then positioned carefully on an “anvil” under the prepared weight, and a metal impact pin is placed atop the sample. The cup is then topped-up with additional LOX.

Finally, the test conductors retreat to a safe distance outside the reinforced test cell, and the weight is released remotely. When the falling weight strikes the pin (delivering the impact energy into the material), the material will either resist ignition or exhibit evidence of reaction (audible sound, light emission, or charring). Based on the test results, the test conductors can then modify the conditions accordingly, adding or subtracting falling distance to determine the impact energy required to ignite the test sample in liquid oxygen.

A Sneak Peek at MIS Testing with WHA Safety Training

Twice a year, WHA hosts technical professionals at its Test and Training facility for four days of intensive oxygen safety training. During their time in Las Cruces, New Mexico, the participants get to tour WHA’s facilities and see several live ignition and combustion tests in oxygen, including a LOX mechanical impact sensitivity test.

Just last week, 21 people came from all over the world (some as far as Japan and New Zealand!) for the latest Level 4: O2 Aware training event. In the following video, you’ll get a sneak peek behind the scenes of the training experience. During this test, a 20-pound weight is suspended 1100 millimeters (43.3 inches) above the anvil, imparting energy of approximately 98 joules. Watch as Combustion and Forensic Engineer Joe Whitehead introduces the live test, which is also paired with new high-speed video for an even closer look at the results.

Share this entry

Related Articles

Battery Safety Insights with Nic Linley, Electrical Engineer

Battery technology continues to evolve rapidly in the 21st Century, powering an expanding array of devices and…

Nonmetals Oxygen Compatibility Requirements: Guide to CGA/EIGA Compliance

The Compressed Gas Association (CGA) and European Industrial Gases Association (EIGA) have harmonized key documents providing guidance…

WHA Launches Oxygen Equipment Supplier Certification Program

Ignition and combustion hazards are present in almost all oxygen and oxygen-enriched systems, and catastrophic fires have…

Request an expert

consultation

Contact us to request a free consultation with an experienced engineer who can help you better understand your needs and our solutions.