Understanding Oxygen Hazard Analysis

Ignition and combustion hazards are inherent in all oxygen and oxygen-enriched systems, regardless of the application. WHA has investigated fires in nearly every industry that uses oxygen. This fire history is evidence that a proper analysis of oxygen hazards is critical to avoiding fires and ensuring the safety of your personnel and equipment.

“We find that most oxygen fires we investigate could have been prevented had a risk analysis been performed on the system or equipment beforehand,”

Elliot Forsyth, WHA International, Inc.

“We find that most oxygen fires we investigate could have been prevented had a risk analysis been performed on the system or equipment beforehand,” explains WHA engineer Elliot Forsyth. “In fact we use a method very similar to hazard analysis in order to determine the cause of an oxygen fire. Often new data is developed in the process. We use this data and certainly the experience gained when we perform future hazards analyses on oxygen systems and equipment.”

How is oxygen dangerous?

How is oxygen dangerous?

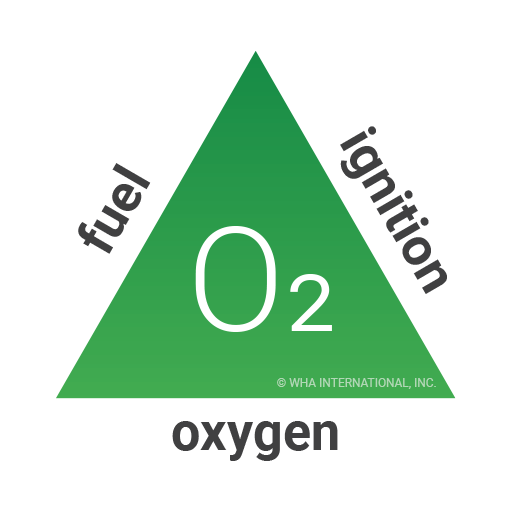

Three basic ingredients are required for any fire to begin: fuel, oxidizer, and ignition (often a heat source). In our oxygen safety training courses, we illustrate these three elements in a “fire triangle.”

Oxygen is a strong oxidizer, and when oxygen concentrations and pressures are increased, materials generally become more flammable and require less energy to ignite. In fact, many materials that are not flammable in air (comprised of only 20.9% oxygen), become flammable in pure oxygen, especially when used under pressure. Many people are surprised to learn that even common engineering metals such as carbon steel and stainless steel are flammable if ignited in high-pressure oxygen.

Further, if an oxygen system is not properly cleaned, small contaminants (even those imperceptible by the naked eye) can ignite and lead to a vigorous fire. Once the reaction is started, the fire can quickly spread through a “kindling chain,” where one flammable material ignites another, possibly leading to an explosive burnout.

Are you curious about how different materials react in oxygen?

Check out our free Oxygen Compatibility Materials Database to review thousands of data points from hundreds of materials tested for flammability and ignition in oxygen-enriched atmospheres according to international standards.

How can hazards be identified?

A large portion of our consulting and testing work at WHA International has to do with oxygen hazard analysis. Our methods arebased on our engineers’ work with ASTM International Committee G04 as well as their extensive experience in oxygen system design, testing, and forensic investigation of oxygen fires. WHA’s hazard analysis approach has now become standard methodology throughout many industries and is consistent with requirements presented by international standards organizations.

The primary objective of any oxygen hazard analysis is to identify system-level and component-level fire hazards and make recommendations to minimize both the probability and consequence of an ignition event. Accomplishing this objective requires evaluating:

- the specific oxygen-enriched environment,

- the materials of construction,

- the likelihood of ignition,

- and the effects of a fire both internal and external to a component.

It is important to note that although an oxygen hazard analysis may consider the effects of other hazards outside of the risk of fire (e.g., compressed gas hazards, cryogenic liquid hazards, pressure system hazards, toxicity hazards, or others), the primary objective remains focused on analyzing fire hazards in oxygen systems and components.

Want to learn more about the WHA’s industry-leading hazard analysis approach?

Download this overview of our 7-step oxygen hazard analysis overview here.

How can risk be mitigated?

Often, potential hazards represent unacceptable risk. Further steps may be necessary to mitigate or reduce the probability and/or consequences of ignition. These measures can include:

- materials changes,

- component or system design changes,

- operating or maintenance procedure changes,

- and/or protecting personnel and equipment with barriers or remote operation.

We simplify oxygen safety

WHA uses innovative, data-driven tools to help clients understand, evaluate, and mitigate the risks associated with oxygen. Our expertise is based on decades of testing and failure analysis experience. We’re specially qualified to work with everything from large industrial oxygen piping systems to small high-pressure oxygen equipment.

Hazard analysis

Our experienced engineers are available to provide several levels of hazard analysis consulting to fit your unique needs. Our state of the art test facility is also equipped to perform materials and component testing if needed.

Technical training

We also provide multiple levels of technical training to help your staff better understand the hazards associated with oxygen. Our Level 4: O2 Analyze course provides everything your personnel need to understand and perform oxygen hazard analyses on their own systems and equipment.

Please contact us to schedule a free consultation with one of our experienced engineers. We would be honored to simplify oxygen safety for your organization.

“As an engineer, hazard analysis is one of the most personally rewarding things we do at WHA, knowing that our review of equipment or systems will ultimately increase our client’s knowledge and safety.”

Elliot Forsyth, WHA International, Inc.

Share this entry

Related Articles

Oxygen Cleaning Service Team Receives Vendor Award

WHA’s oxygen cleaning service team recently received recognition from its client, Trace-A-Matic, for excellent service in a…

Oxygen Cylinder Safety

An oxygen tank, or “oxygen cylinder,” is a pressurized container that stores and transports oxygen in its…

WHA’s Hydrogen Fire Risk Management Philosophy

Simulation of hydrogen deflagration, an explosion that occurs when hydrogen gas mixes with air or oxygen and…

Request an expert

consultation

Contact us to request a free consultation with an experienced engineer who can help you better understand your needs and our solutions.