WHA Provides Oxygen Ventilator Fire Risk Analysis

The world needs ventilators, and ventilators use medical oxygen. As the demand for oxygen ventilators increases, new designs are rapidly being developed. WHA has investigated fires in nearly every industry that uses oxygen, including medical oxygen ventilator fires. New ventilator designs need careful consideration of the oxygen fire risk, and WHA has the experience needed to help ventilator manufacturers analyze and mitigate the risk. Even if the design has a successful history of use without fire incidents, modifications to design, including changes to components or materials, can change the fire risk.

BACKGROUND: Why is oxygen so dangerous?

Oxygen is not a fuel (like gasoline or hydrogen). It does not burn. So why is it so dangerous, especially if we breath it?

Oxygen is an oxidizer that allows other fuels to burn. Pure or “enriched” oxygen environments are hazardous because materials can ignite more easily and burn more vigorously than in air. Materials like aluminum and many plastics don’t burn in our normal air atmosphere (approximately 21% oxygen), but they will burn under elevated oxygen concentration and/or pressure.

Technical training experts here at WHA often rely upon the “fire triangle” to illustrate the relationship between fuel, oxidizer, and ignition source.

REFERENCES: Oxygen and Ventilator Fire Risk

The Association for the Advancement of Medical Instrumentation® (AAMI) released guidance documents on April 8, 2020, developed by the AAMI COVID-19 Response Team. AAMI CR501:2020, Emergency Use Ventilator (EUV) Design Guidance document provides “targeted design constraints to enable rapid development of emergency use ventilators (EUV) to treat patients with COVID-19 respiratory failure.”[i] This document references the considerations in IEC 60601-1, 11.2.2 for an oxygen rich environment.[ii]

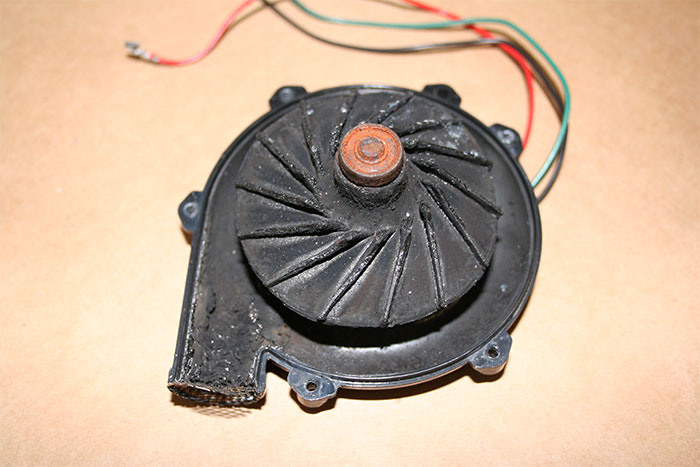

ISO/IEC 60601 is a series of safety standards for medical electrical equipment (ME equipment). Manufacturers of medical devices with electrically powered equipment should demonstrate compliance with this international standard. WHA analyzes designs against the specific requirements related to oxygen hazards that are contained within IEC/ISO 60601-1 (subsection 11.2.2.1). Since the electrically powered componentry in most ventilator designs are located outside the oxygen gas path (i.e., not directly exposed to oxygen during normal operation), electrical equipment exposure to an oxygen enrichment can only develop via failure modes (e.g., leaks). Leakage should be considered a credible failure mode. Therefore, the IEC/ISO 60601-1 requirements would apply to electrical powered equipment that could be exposed to oxygen concentrations above 25% as a result of either an external leak (e.g., seals and hose connections) or internal leaks (e.g., check valves).

ISO 15001 is a standard that should be considered for the oxygen gas system to help specify oxygen cleanliness and evaluate the oxygen compatibility of the system, its components, and materials.[iii] ASTM G126 defines oxygen compatibility as “the ability of a substance to coexist at an expected pressure and temperature with both an oxidant and a potential source(s) of ignition within a risk parameter acceptable to the user.”[iv] The oxygen compatibility evaluation approach outlined in ISO 15001 is consistent with WHA’s Oxygen Fire Risk Analysis (OFRA) methodology.

APPROACH: oxygen fire risk analysis (OFRA)

WHA routinely performs OFRAs to support our customers’ design reviews. Our methods are based on our engineers’ work with ASTM International Committee G04 and ISO technical committees, as well as their extensive experience in oxygen system design, testing, and forensic investigation of oxygen fires.

The primary objective of any oxygen hazard analysis is to identify system-level and component-level fire hazards and make recommendations to minimize both the probability and consequence of an ignition event. Accomplishing this objective requires evaluating:

- the specific oxygen-enriched environment,

- failure modes that could increase oxygen pressure, concentration, temperature, and levels of potential contamination,

- materials of construction,

- probability of ignition,

- and the consequence of a fire both internal and external to a component.

Customized for ventilators, our OFRA approach also incorporates the requirements of IEC 60601-1 Section 11.2.2 and ISO 15001 so our customers receive a complete analysis for medical oxygen ventilator fire risks.

CONTACT US: No-Cost Initial Consult

In response to the urgent and critical need of ventilators for COVID-19 patients, WHA is offering a no-cost initial consult of the design. WHA can rapidly review/establish confidentiality agreements to permit document sharing design (if necessary) and initiate a teleconference to provide a preliminary review of a ventilator. If additional analysis is required then WHA has various levels of hazard/risk analysis to meet your timeline, scope, and budget.

[i] AAMI CR501:2020, Emergency Use Ventilator (EUV) Design Guidance. https://www.aami.org/news-resources/covid-19-updates/covid_cr

[ii] IEC 60601-1-11:2015, Medical electrical equipment — Part 1-11: General requirements for basic safety and essential performance — Collateral standard: Requirements for medical electrical equipment and medical electrical systems used in the home healthcare environment, International Organization for Standardization

[iii] ISO 15001:2010, Anaesthetic and respiratory equipment — Compatibility with oxygen, International Organization for Standardization

[iv] ASTM G126-16, Standard Terminology Relating to the Compatibility and Sensitivity of Materials in Oxygen Enriched Atmospheres, ASTM International, West Conshohocken, PA, 2016

Share this entry

Related Articles

Nonmetals Oxygen Compatibility Requirements: Guide to CGA/EIGA Compliance

The Compressed Gas Association (CGA) and European Industrial Gases Association (EIGA) have harmonized key documents providing guidance…

WHA Launches Oxygen Equipment Supplier Certification Program

Ignition and combustion hazards are present in almost all oxygen and oxygen-enriched systems, and catastrophic fires have…

Oxygen Cleaning Service Team Receives Vendor Award

WHA’s oxygen cleaning service team recently received recognition from its client, Trace-A-Matic, for excellent service in a…

Request an expert

consultation

Contact us to request a free consultation with an experienced engineer who can help you better understand your needs and our solutions.