WHA is uniquely qualified to meet your oxygen safety needs

Due to the inherent risk of fire, safety is a critical concern for any industry that uses oxygen. Materials become more flammable when oxygen concentrations and pressures are increased and the energy required to ignite these materials is reduced. WHA International, Inc. has investigated hundreds of incidents in which improper oxygen use has resulted in costly property damage, personal injury, and even death.

Oxygen hazards can seem mysterious, but our experienced engineers are dedicated to simplifying oxygen safety. We work with clients who share our “safety first” attitude, providing the knowledge and tools they need to use oxygen safely and confidently.

When selecting a partner in oxygen safety, the choice is clear: WHA is uniquely qualified to provide specialized solutions to your complete range of oxygen safety needs.

WHA’s oxygen safety expertise is built upon failure analysis experience

WHA International Inc, has a highly specialized background in failure analysis of oxygen systems and components. Our extensive experience with oxygen technologies spans all industries and uniquely sets us apart from other technical consulting firms.

This background in failure analysis provides an extensive foundation for our complete range of oxygen safety services. Over 200+ years of combined experience with oxygen technologies informs everything we do, including failure analysis, hazard analysis, testing, safety training, and precision oxygen cleaning. Our standards, materials compatibility data, and Oxygen Fire Risk Analysis (OFRA) methodology are utilized by companies around the world.

WHA has truly distinguished itself worldwide as an industry leader in oxygen safety.

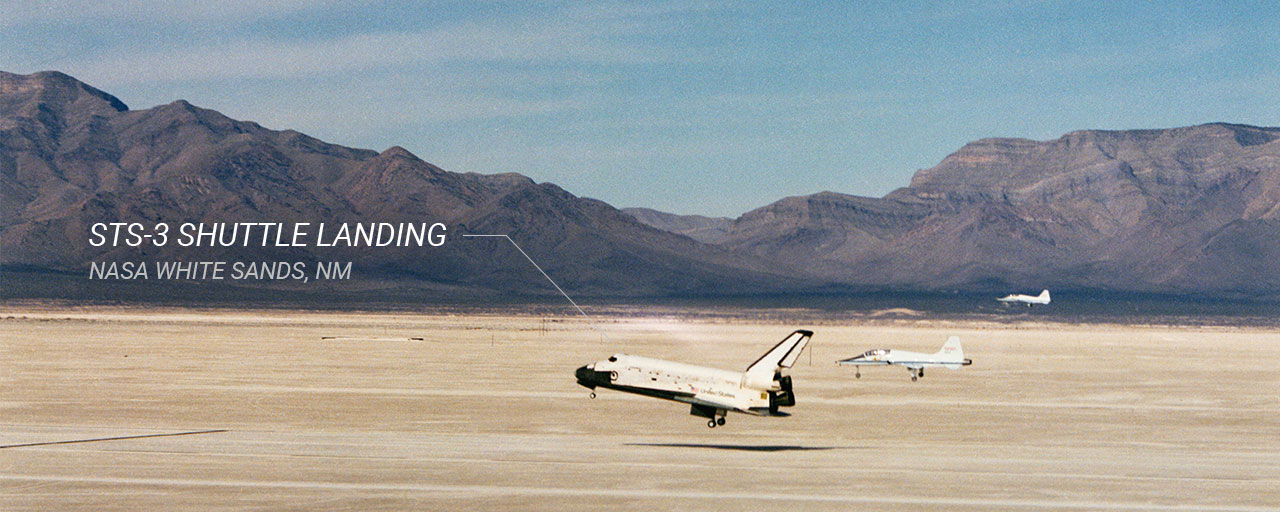

WHA brought NASA’s oxygen expertise to commercial sector

Oxygen safety came into the national spotlight in 1967 following the tragic accident of Apollo 1, and many of WHA International’s engineers built their careers in this burgeoning field at NASA White Sands Test Facility. WHA engineers were among the first to design, fabricate, and implement many of the oxygen and hazardous fluids test systems used by the space program during the Apollo, Space Shuttle, and International Space Station programs.

In the 1980s, WHA’s founders brought their specialized oxygen experience into the commercial sector, and continued providing design, testing, and failure analysis of aerospace oxidizer and hazardous fluids systems, not only for NASA, but for Boeing, Allied Signal Aerospace, and Jacobs Technologies as well.

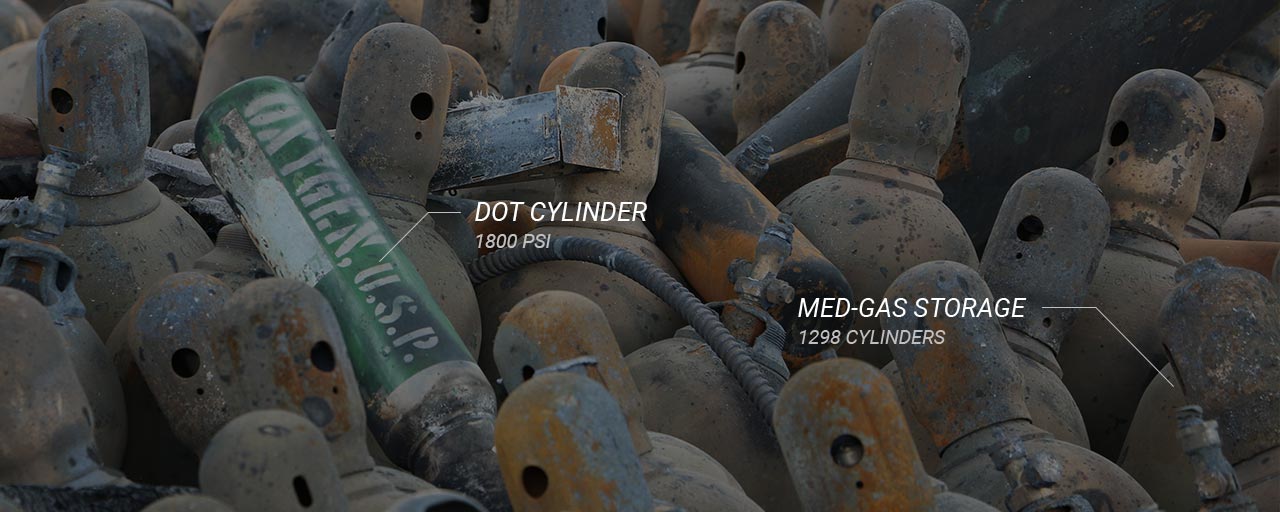

WHA’s oxygen experience spans nearly every industry that uses oxygen

Based on demand, WHA’s oxygen experience soon expanded into the welding, commercial gas, petrochemical, medical oxygen and medical device industries. Our engineers have investigated incidents in almost every industry that uses oxygen and have developed tools to harden systems against oxygen-related fire hazards. These tools have now become industry standards and have been incorporated into several industry best practices.

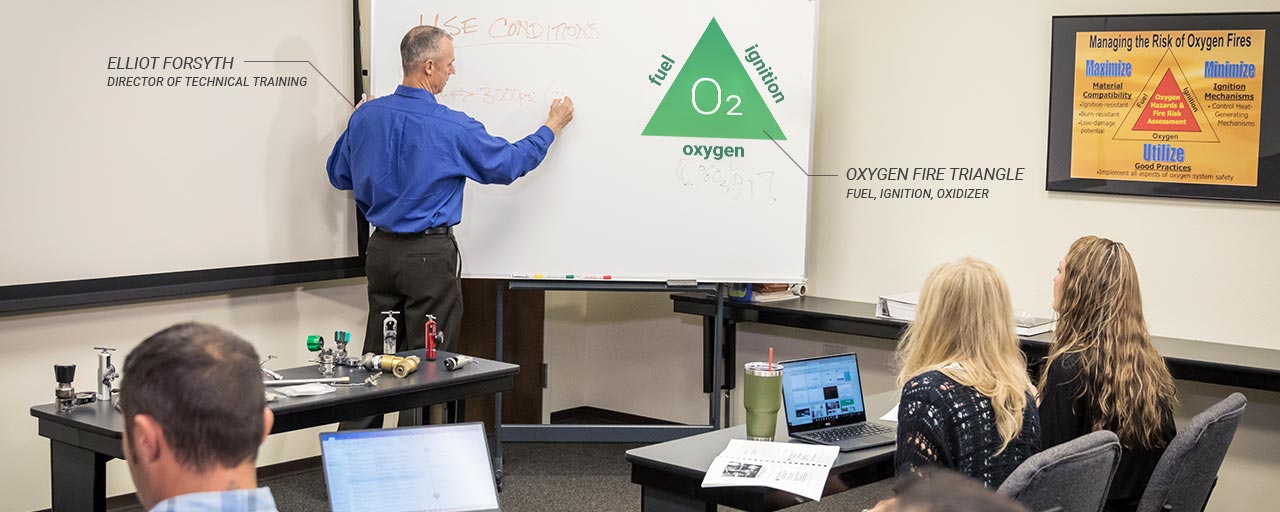

WHA’s oxygen hazards and fire risk training is unsurpassed in the industry

WHA specializes in custom-tailored, technical training for oxygen systems. Our curriculum stresses the “why” behind the “what” of oxygen safety best practices. Our engineers helped pioneer the development of oxygen safety training at NASA and ASTM International, and today they have advanced the content and methods well beyond any other government or industry source.

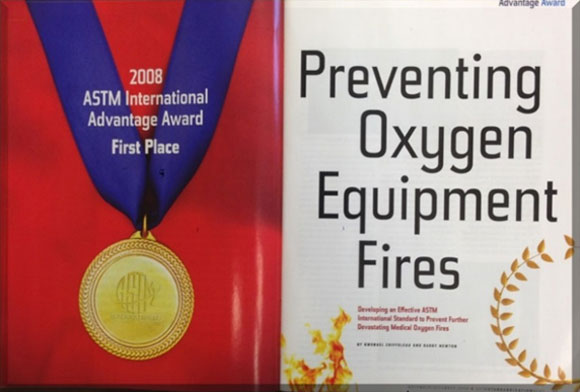

Our engineers literally set the standards on oxygen safety

WHA engineers were founding members of the important ASTM International G04 committee on Flammability and Sensitivity of Materials in Oxygen-Enriched Atmospheres. These engineers hold the honorary title of “ASTM Fellow” and currently act as chairmen of the overall ASTM G04 main and executive committee and the ASTM G04-02 subcommittee on Recommended Practices. They have edited two ASTM G-04Standard Technical Publications (STPs) co-chaired the G04symposiums in Paris, France (2000) and Brisbane, Australia (2003), and published over 100 technical papers.

WHA engineers have participated in the development and/or revision of approximately twenty ASTM standard test methods, guides, and practices. They currently have technical responsibility for several industry-critical standards, including:

- ASTM G93, “Practice for Cleaning Methods for Material and Equipment Used in Oxygen-Enriched Environments”

- ASTM G145 “Standard Guide for Studying Fire Incidents in Oxygen Systems”

- ASTM G72, “Standard Test Method for Autogenous Ignition Temperature of Liquids and Solids in a High-Pressure Oxygen-Enriched Environment”

- ASTM G74, “Standard Test Method for Ignition Sensitivity of Nonmetallic Materials and Components by Gaseous Fluid Impact”

- ASTM G175, “Standard Test Method for Evaluating the Ignition Sensitivity and Fault Tolerance of Oxygen Pressure Regulators Used for Medical and Emergency Applications”

WHA’s unique technical capabilities are unparalleled

The WHA test facility is recognized throughout the world among the leading test facilities for excellence in oxygen testing. Our laboratories are equipped with eight hazardous fluids test cells/areas and house over 20 different material and component flammability or qualification test systems for hazardous environments such as ultra-high-pressure oxygen, liquid oxygen, nitrous oxide, hydrogen/oxygen, hydrogen/air, acetylene/oxygen, acetylene/air, and other cryogenic fluids.

WHA test systems include system or component flammability or qualification testing by gaseous fluid impact, mechanical impact, particle impact, metals ignition and burning in high-pressure oxygen, spontaneous ignition and ignition tolerance in high-pressure oxygen, thermal exposure, accelerated aging, life cycling in air or oxygen and other tests.

Industries worldwide utilize WHA’s test and analysis capabilities, including military branches, industrial gas companies, medical oxygen and device industries, commercial petroleum, liquefied natural gas and petrochemical, welding, SCUBA, energy production, mining, metals production/refining and aerospace companies including the rapidly developing state-of-the-art commercial spaceflight technologies.

Our philosophy puts people first

WHA prides itself in its unique data-driven approach to safety. Beneath the numbers, however, it’s crucial to remember that the business of safety is all about people. Our engineers are devoted to protecting those who work with oxygen and training others to do the same. We apply meticulous care to whatever we do. Whether it’s hazard analysis, testing, or precision oxygen cleaning, our efforts have a direct impact on the wellbeing of our clients.

If you share our safety-first philosophy, give us a call or contact us to arrange a free consultation with one of our specialized engineers. We look forward to serving you in all of your oxygen safety needs.

Share this entry

Related Articles

Oxygen Cleaning Service Team Receives Vendor Award

WHA’s oxygen cleaning service team recently received recognition from its client, Trace-A-Matic, for excellent service in a…

Dr. Gwenael Chiffoleau Assumes CEO Role at WHA

We are thrilled to share some exciting news about a significant transition within our organization. After 34…

Oxygen Cylinder Safety

An oxygen tank, or “oxygen cylinder,” is a pressurized container that stores and transports oxygen in its…

Request an expert

consultation

Contact us to request a free consultation with an experienced engineer who can help you better understand your needs and our solutions.