WHA has exceptional experience and test capability in evaluating electrical sources of ignition in products and flammable gasses and oxygen-enriched environments, including the unique ignition mechanisms associated with ESD, Arc Tracking, and unusual component failure modes. WHA is specially equipped to help uncover the role of a suspected electrical failure in a fire incident, especially in oxygen-enriched or air/oxy-fuel atmospheres. We investigate the origin, root cause, ignition source, kindling chain, and fuel that lead to fires and can provide statistical analysis from unit failure rates and population information as well as deterministic failure rates applied from electrical failure reconstruction testing.

Electrostatic Discharge (ESD)

Electrostatic Discharge is a known source of ignition in the fuel gas industry and has been considered to be a potential source of ignition of several oxygen related fires that occurred in hyperbaric chambers. WHA has participated in many ESD related investigations and performed a critical role in determining if ESD was a likely cause. WHA has experience in analyzing ESD problems related to human body discharge and static accumulation hazards associated with low conductivity fluid.

Lightning Strikes

Investigate the propensity of lightning from inclement weather having caused fire on building structures.

- Analysis of evidence for consistency with lightning strike cause

- Analysis of StrikeNET, FaultFinder, and weather station data for propensity of lightning strike in area

Arc Tracking

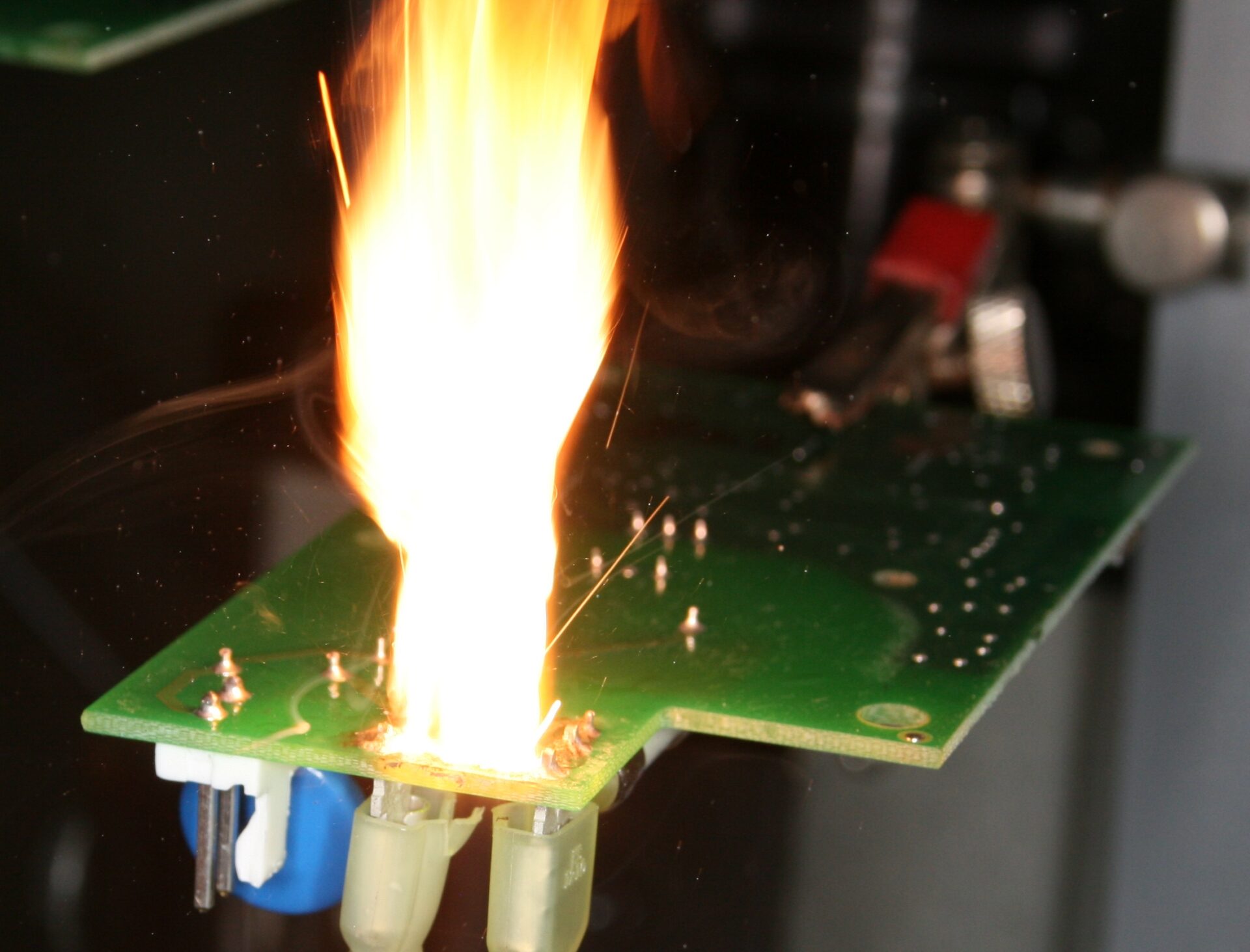

Arc Tracking is the result of electrical current flow through material that is meant to be electrically insulative (resisting the flow of electrical current) and has been demonstrated in testing by WHA on many occasions in normal air and oxygen-enriched atmospheres. Arc tracking may occur in either AC or DC electrical systems and both high and low voltage systems are susceptible. Radiation in the form of heat and/or UV light is known to break down the dielectric strength of common electrical insulation material such as PVC and FR-4 (common in circuit board and electrical wire manufacturing). Common causes that may lead to arc tracking include (but are not limited to): failing electrical components undergoing thermal runaway events, high resistance connections, conductive contamination on a circuit board, voltage transients from non-“clean” power sources.

WHA has evaluated and tested Arc-Tracking development on:

- Printed Circuit Boards

- Cables/wiring

- Switches

- Connectors

- AC Outlets

Failure of Battery Systems

Battery systems may contain significant amounts of energy and can become the source of ignition for a fire, including fires involving oxygen, hydrogen, or other oxidizers or fuel gases. It is essential to have an investigator experienced in battery system failure modes who can analyze physical evidence and determine the potential contribution from batteries and if an oxidizer or fuel gas was involved. WHA has experience investigating fires related to lithium-ion and lead acid batteries in:

- Electric vehicles

- Utility power station backups

- Ventilators, respirators, and other medical devices

- Electrolysis systems

- Hydrogen fuel cells

- And more

Equipment Investigated

- Ceramic Capacitors

- Field Effect Transistors (MOSFET, FET)

- Metal Oxide Varistor (MOV)

- Industrial and High Energy Equipment:

- Power Factor Correction Capacitors

- Electric Vehicle Motor Drives (Inverters)

- Compressor and Motors

- Controllers

- Medical Devices and Oxygen Handling Equipment where electrical sources of ignition have been evaluated:

- Oxygen Concentrators

- Ventilators

- Continuous Positive Airway Pressure (CPAP) devices

- Respirators

- Nebulizers

- Hyperbaric Chambers

Hazard Analysis Method

WHA utilizes industry standard Event Tree and Fault Tree Analysis to identify and evaluate failure sequences and potential cascading fault conditions. The industry standards for Qualitative and Quantitative Fault Tree Analysis and Failure Probability/Reliability Analysis have been expanded by WHA engineers to both evaluate and mitigate product fire risks; but, also to determine likely failure modes that explain fire patterns.

- Qualitative Fault Tree Analysis

- CASE STUDY: FHP Study and Report

- Medical Device Design Evaluation according to ISO/IEC 60601-1:

- CASE STUDY: FHP Study and Report

Industry Insights & Case Studies

Defend against oxygen fires in medical electrical equipment

WHA Engineer Nic Linley explains the risks and paths to compliance for medical electrical equipment that handles oxygen.

Industry Spotlight: Hyperbaric Oxygen Safety

Of all the applications for medical oxygen, hyperbaric oxygen (HBO2) chambers present some of the most complex…