Battery Safety Insights with Nic Linley, Electrical Engineer

Highlights

- While battery failures are rare, their consequences can be severe.

- Batteries require unique fire safety considerations, especially in oxygen or hydrogen applications.

- WHA provides failure analysis, hazard analysis, and custom testing services for battery technology.

Battery technology continues to evolve rapidly in the 21st Century, powering an expanding array of devices and applications. As with any growing technology, this progress comes with new safety challenges.

While battery failures are rare, their consequences can be severe.

We spoke with Nic Linley, a Senior Electrical Engineer at WHA International, to learn more about battery safety and how WHA is helping industries navigate hazards safely.

Applications of Li-Ion and Lead-Acid Batteries

When it comes to batteries, the adoption of two technologies is growing faster than ever before: lithium-ion (Li-ion) and lead-acid batteries. Both types have unique advantages that make them suitable for various applications.

Lithium-Ion Batteries

Lithium-ion (Li-ion) batteries have become ubiquitous in our daily lives.

“Their major advantages have to do with their ability to be charged quickly,” says Linley. “They’re also good for continuous use and full discharge.”

These characteristics make Li-ion batteries ideal for a wide range of applications, including:

- Small consumer electronics like laptops and cell phones

- Electric vehicles (EVs)

- Medical devices, especially for life support systems and portable equipment

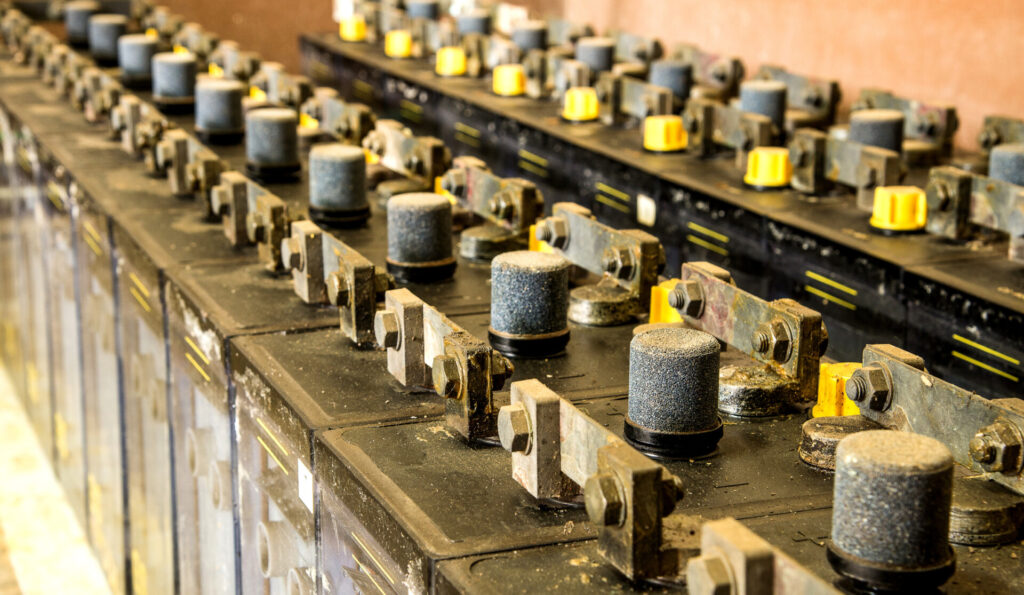

Lead-Acid Batteries

Lead-acid batteries have been a staple under the hoods of our cars for many decades, and they continue to play a crucial role in many applications.

“Lead-acid batteries have enormous power discharge capabilities, but unlike Li-ion batteries, they are only designed to fully discharge occasionally. Doing so too often can damage their performance.”

Common uses include:

- Starter circuits in vehicles

- Backup power for power substations, hospitals, and airliners

- Electric forklifts

WHA’s Role in Battery Safety

WHA International specializes in safety services for oxygen, hydrogen, and other hazardous fluids, so where do batteries fit in?

“First and foremost, we investigate fires,” Linley says. “Batteries are known sources of ignition—of heat and energy. We often have to rule them in or out of fire investigations.”

Those fire hazards are amplified when batteries are used in conjunction with oxygen or hydrogen. For example, much of WHA’s experience with battery safety stems from involvement with medical electrical equipment that uses oxygen.

“Battery backups are now required for many medical devices, especially life-support systems like ventilators. They must sustain life long enough for the operator to switch out the device if there’s a problem.”

Failure Analysis: WHA’s Investigations into Battery-Related Fires

WHA has investigated numerous incidents involving both Li-ion and lead-acid batteries. Linley highlights a few notable case examples.

Lead-Acid Battery Explosions at Power Substations

WHA has investigated incidents involving lead-acid batteries at power substations. One instance included batteries that had “exploded” during use.

Based on the evidence they observed, Linley and his fellow investigators identified the probable cause of the explosions: “We determined that lead sulfate crystals were forming within the cells, probably due to undercharging batteries and leaving them in a discharged state for extended periods. This process can lead to electrolysis of the electrolyte, creating a potentially explosive hydrogen-oxygen atmosphere within the battery.”

Unraveling the Mystery Around Vehicle Fire Litigation

WHA has provided forensic investigation and expert witness services for multiple vehicle fire cases. Batteries are always a potential ignition source in vehicle fires, but it takes an experienced investigator to determine if electrical arcing is the cause—or the effect.

“In one case, the plaintiff used signs of electrical arcing to suggest that the fire originated with the electrical system and involved the battery,” Linley recalls. “However, that arcing can also occur after an unrelated fire melts the shielding on electrical wires. NFPA 921 warns against this assumption. ‘Arc mapping’ analysis presents unique challenges in vehicle fires and may not always be useful at establishing the origin or timing of a fire.”

Ultimately, WHA was able to analyze the burn patterns, tracking down the more likely origin of the fire, which was consistent with the physical evidence and witness statements, leading to a favorable outcome for the defendants.

Medical Device Fires Involving Li-ion Batteries

WHA investigated a series of medical device fires in recent years, which could be traced back to their batteries. WHA’s investigations revealed a complex chain of events:

- Certain conditions could cause Li-ion cells to fail and vent, allowing the electrolyte to leak.

- Conductive electrolyte would leak onto the circuit board, causing electrical arcing.

- Heat from arcing initiated thermal runaway in the remaining cells, leading to a fire.

The investigation findings led to multiple system design changes to mitigate the hazards, including modifications to the charging circuit, changes to the battery type and design, and changes in the equipment configuration to prevent cascading failures.

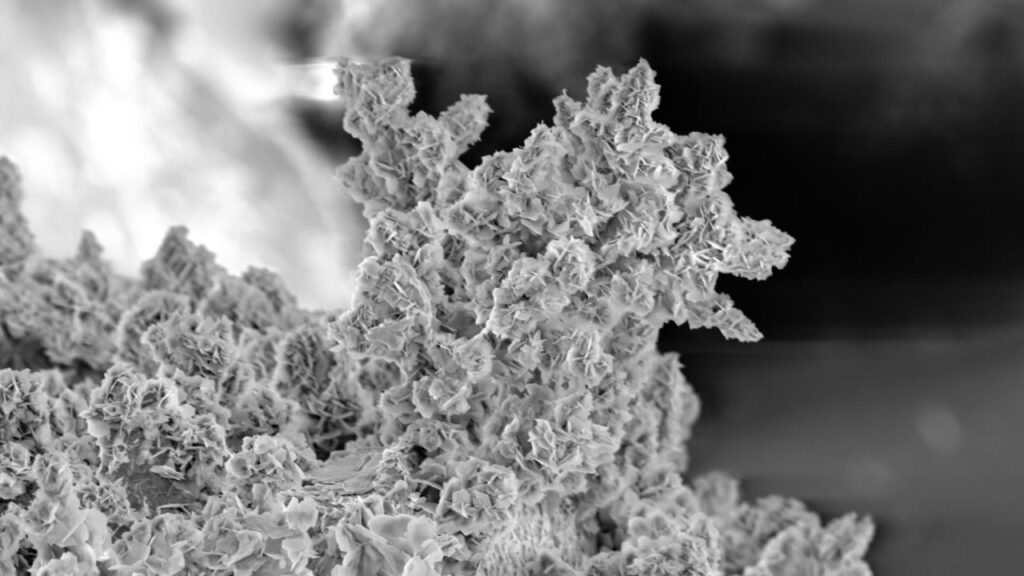

Reliability Issues with Li-ion Cells

WHA has also been involved in multiple cases considering manufacturing defects and dendrite growth in Li-ion cell failures.

“Dendrite growth can occur naturally in any Li-ion cell if charged too quickly. It is a known issue.” Linley explains. “These microscopic conductive crystals can create internal short circuits, leading to cell failure.”

Today, the supply of Li-ion batteries struggles to keep up with the demand, and companies like WHA can help manufacturers quality control unvetted suppliers from overseas.

Learn more about WHA’s electrical failure analysis capabilities

Hazard Analysis: Improving Battery Safety

Of course, Linley always prefers to engage in conversations about battery safety before a fire occurs.

WHA conducts comprehensive hazard analyses for Li-ion and lead-acid battery systems, especially those used with oxygen or hydrogen.

“We look at how their battery compartment is designed, how the cell pack is designed, the positioning of the cells and the circuit board. We look at their fuse protection leading in and out of the battery,” Linley explains.

Another key aspect of WHA’s work is assessing the effectiveness of barrier protection methods.

“If this device catches on fire, what are the consequences? A sufficient barrier will isolate the fire, preventing it from spreading to the rest of the device or harming the user.”

This effect illustrates one of the key differences in battery hazard analysis. It requires a unique approach that differs from many other electrical applications. When a device is plugged into the wall, there are typically fuses and protective measures to cut electricity in case of a failure. Battery-powered devices can never do so completely. Designers must consider that a potential power and heat source is always present within the system.

Learn more about WHA’s electrical fire safety services

Custom Testing: Generating Data to Improve Safety

Both fire investigations and hazard analysis often depend on experimental data to find answers and drive safety improvements.

For instance, WHA’s unique custom testing capabilities enable it to perform thermal runaway tests to evaluate the effectiveness of barrier protection.

“We can start a thermal runaway in the cells and look at the consequences around it. What temperature, smoke, and fire emits around the barrier?”

Explore WHA’s medical electrical equipment oxygen testing capabilities

Conclusion: Navigating the Future of Battery Safety

It’s worth reiterating that battery failures are rare, but when they do occur, the consequences can be significant.

Overall, battery-powered devices are becoming safer, and the failure rate is decreasing. However, the number of battery-powered devices on the market is growing exponentially, which means more incidents occur every year.

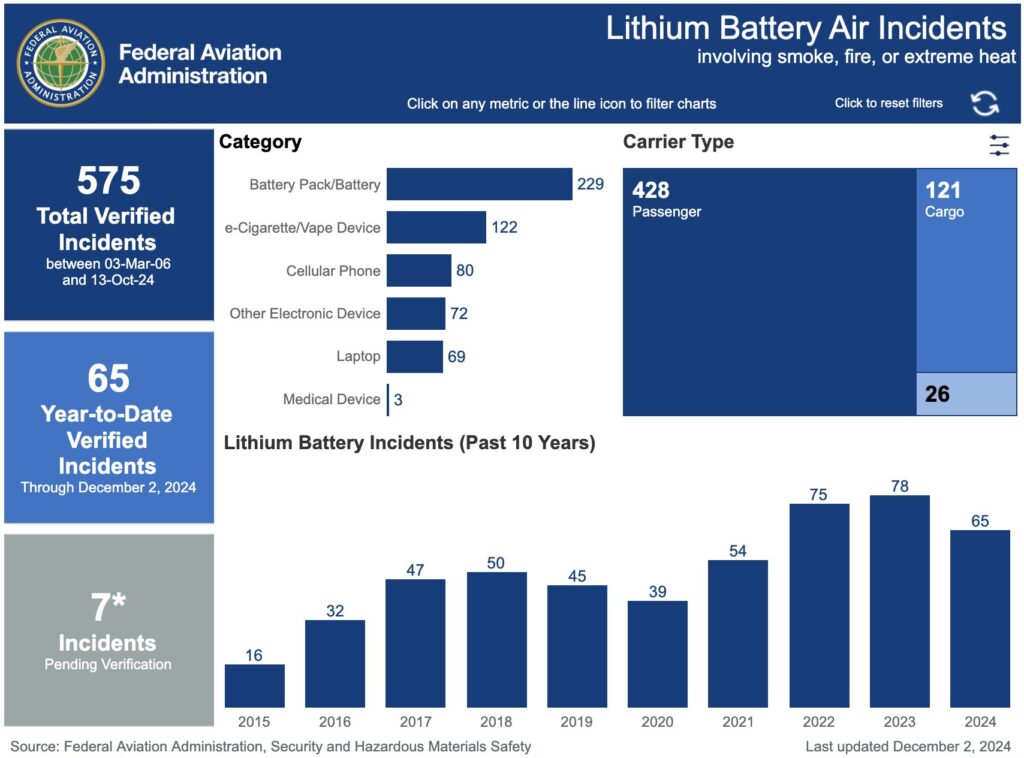

The Federal Aviation Administration provides an excellent overview of the numbers, as it has tracked all reported Li-ion battery incidents in airplanes and airports since 2006.

The first ten years of reporting (2006-2016) averaged only 11 incidents per year. In the first years of this decade (2020-2024), we’ve averaged over 60 incidents per year, well over a 500% increase.

By uncovering the truth behind battery failures and helping to improve safety measures, WHA is playing a crucial role in ensuring the safe progression of battery technology.

Share this entry

Related Articles

Hydrogen Tank Explosion Demonstration

Typically, hydrogen is safely stored as a purified gas or liquid. Although hydrogen is a fuel, it…

Hydrogen Cleaning: Ensuring Safety and Reliability in Pressurized Hydrogen Systems

Hydrogen is an increasingly important and prominent energy carrier, with applications ranging from fuel cells to electrolyzers…

Battery Safety Insights with Nic Linley, Electrical Engineer

Battery technology continues to evolve rapidly in the 21st Century, powering an expanding array of devices and…

Request an expert

consultation

Contact us to request a free consultation with an experienced engineer who can help you better understand your needs and our solutions.