WHA Papers Impact Oxygen Safety in Industry

How do engineers and scientists around the world collaborate and inform themselves on new developments in the highly specialized field of oxygen safety? Since 1975, ASTM Committee G04 has been at the center of innovation and communication. Engineers at WHA International were among the founding members of this committee in 1975, and since then, staff members have continually held leadership positions in the organization.

Every three to four years, this committee hosts a symposium in an effort to further the science of oxygen safety worldwide. Companies from many industries around the world gather at this event to present peer-reviewed technical papers, collaborate, and network.

About the upcoming ASTM symposium on oxygen safety

This year, the 15th International Symposium on Flammability and Sensitivity of Materials in Oxygen-Enriched Atmospheres will be held April 29-30 in Prague, Czech Republic. The event is open to the public — scientists, engineers, and technical personnel responsible for selecting materials or conducting research on the ignition and fire risk of materials used in oxygen or oxygen-enriched systems.

You can register for the symposium here.

WHA equips and collaborates with industry through ASTM papers

This year, WHA International is submitting eight of the 25+ papers that will be presented. These papers have been created in collaboration with invaluable insights from several industry partners, including Air Liquide, Flowserve, and Linde-Praxair. Click on any of the titles below or read on for information and a brief synopsis on each presentation. A full list of all papers, including abstracts is available via the ASTM website.

- Evaluation of Metals Flammability Using Extinguishment Thickness

- Bagging Material Analysis for Cleanliness Preservation

- Failure Analysis of a LOX Valve: Internal Fire Only

- An Approach to Understanding the Chemistry and Risks of Operating Aging Oxygen Pipelines supplied by Compressors

- A Critical Analysis of Adiabatic Compression Test Methods

- Oxygen Compatibility and Safe-Use Criteria for Non-Metallic Materials

- Configurational Oxygen Compatibility Testing of Nonmetals

- Quantitative Probability Analysis of Particle Impact Ignition in an Oxygen Control Valve

Evaluation of Metals Flammability Using Extinguishment Thickness

Authors: Jared Hooser, James White*, Eric Thom*, Gwenael Chiffoleau, Elliot Forsyth, Barry Newton

*Praxair, Inc., a member of the Linde group

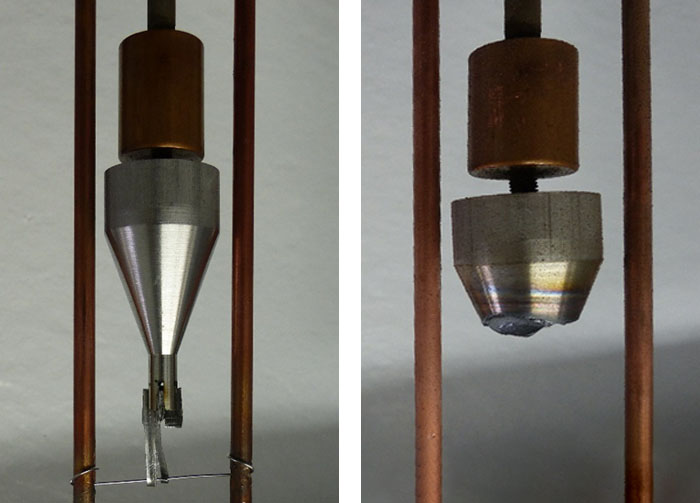

The ASTM G124 test methodology is critical in assessing the flammability of metals in oxygen applications, but it’s limited in providing specific data on how variations in the metal’s thickness affect flammability. The current test standard only provides provisions for testing a 3.2 mm rod, and this paper proposes a practical modification of the existing test method to incorporate a metal rod of tapered thickness (3.2mm and larger). This change will generate new data to determine the “extinguishment diameter” of the metal in question, providing valuable insights to oxygen system and component designers. The oxygen industry as a whole is encouraged to evaluate and consider this approach for a new test method.

Bagging Material Analysis for Cleanliness Preservation.

Authors: Travis Gwynne, Wallace Foster, Gwenael Chiffoleau, Barry Newton

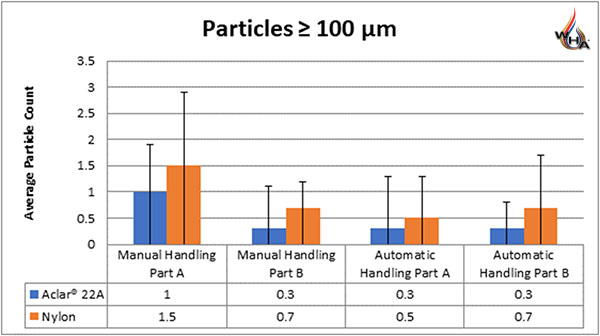

Contamination represents a significant fire risk in any oxygen system. Even the meticulous process of oxygen precision cleaning can generate particulate which is itself a risk. There are currently no standards for evaluating the contaminating effects of bagging, handling, and transportation after oxygen cleaning. In this paper, WHA staff members outline a new test method used to evaluate two bagging materials: Nylon-6 and Aclar® 22A. These tests resulted in valuable comparative data and outline how industry can use a similar method to test and identify safe bagging materials in the future.

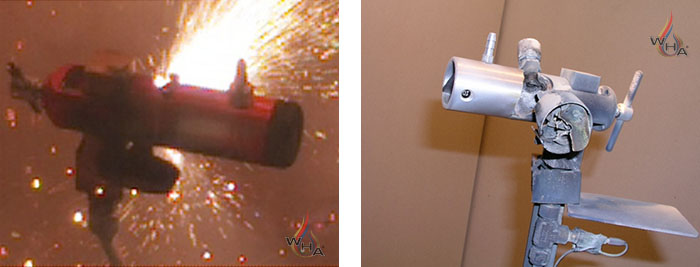

Failure Analysis of a LOX Valve: Internal Fire Only.

Authors: Gwenael Chiffoleau, Derek Miller*, Barry Newton

*Air Products & Chemicals, Inc. Emmaus, Pennsylvania, USA

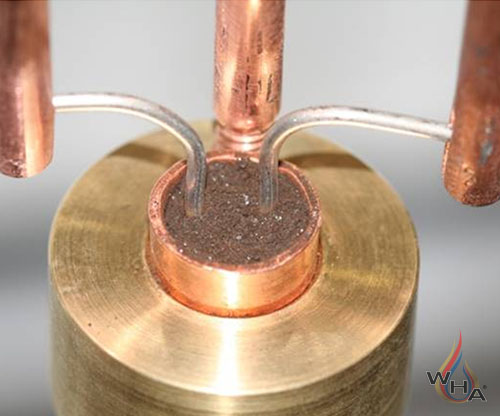

This paper presents a failure analysis of an internal fire in a liquid oxygen (LOX) gate valve. The fire event did not breach the pressure containment of the valve or surrounding associated piping, so the exact timing of the fire event was not clearly discernible, but the consequence of breach would have been catastrophic. The findings reveal important contributing factors and recommendations to help prevent hydrocarbon contamination and ignition through repetitive mechanical impact (vibration) in similar applications.

An Approach to Understanding the Chemistry and Risks of Operating Aging Oxygen Pipelines supplied by Compressors

Authors: Dr. John Somavarapu1, Charles N. Harper2, Gwenael Chiffoleau, Barry Newton

1 Integrity Services Group of Companies, 2Air Liquide

Many decades of operation are creating a growing challenge in considering the reaction behavior, risks, and operation of aging industrial gas oxygen pipelines. The formation of oxides of carbon steel pipe “rust” is possible (sometimes in surprising quantities), which can impact operations and potential operational risk. This paper is designed to help operators and management of pipeline networks understand the chemistry and risks of flammability. Real-world findings are presented to help contextualize the ongoing operations and risk.

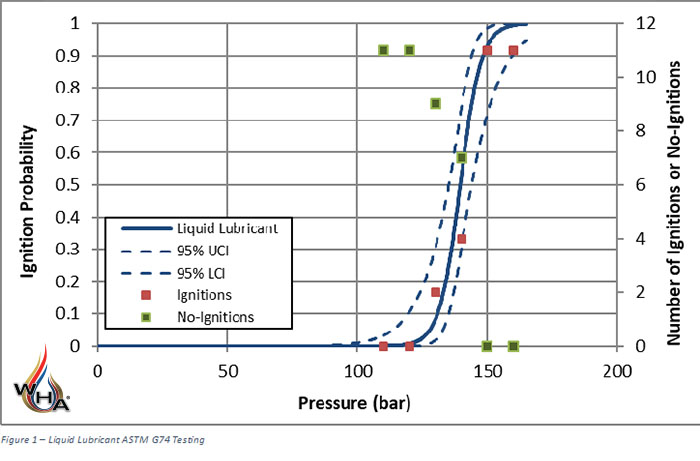

A Critical Analysis of Adiabatic Compression Test Methods

Authors: Barry Newton, Theodore Steinberg, Gwenael Chiffoleau

Industry test methods such as ASTM G-74, ASTM G-175, ISO 21010, and ISO 10524 have been used for many years to evaluate nonmetallic materials and components for use in high-pressure oxygen, but WHA personnel have found that the severity of this test is widely overestimated. This paper offers a new analysis of the data produced by the industry standards to help oxygen practitioners better apply the test methods for safer designs.

Oxygen Compatibility and Safe-Use Criteria for Non-Metallic Materials

Authors: Barry Newton, GwenaelChiffoleau, Elliot Forsyth

Nonmetals can pose a fire risk in oxygen systems and should be tested to qualify their use in oxygen. Several industry standards (including ASTM G63 and ISO Standard 21010) help establish “safe-use” criteria for these non-metals, but there appears to be wide-spread misunderstanding in industry’s concept of “maximum use pressure” and “maximum use temperature.” This paper summarizes the methodologies for testing and evaluating the oxygen compatibility of nonmetallic materials and provides recommendations for clearer acceptance criteria on the use of non-metallic materials in oxygen service.

Configurational Oxygen Compatibility Testing of Nonmetals

Authors: Greg Odom, Kevin Smith*, Rob Carlson*, GwenaelChiffoleau, Barry Newton

*Flowserve Corporation, Springville, Utah, USA

Nonmetals can pose a fire risk in oxygen systems and should be tested to qualify their use in oxygen. Nonmetals not meeting the requirements of the oxygen pressure surge testing (ISO 21010, 2017) can be tested in their actual operating configuration. However, this type of testing on a large industrial piping valve is not feasible with existing test standards and most test facilities. This paper outlines the successful design of a special test fixture that enables oxygen pressure surge testing to be performed on O-rings and lubricants in their use conditions, within a representative assembly. This new test method opens new opportunities for testing large industrial piping valves, safely and conveniently in a lab environment. This test method may also enable soft goods to be qualified for safe use at pressures and temperatures that are higher than the max use pressure/temperature for each individual soft good as established by current test methods.

Quantitative Probability Analysis of Particle Impact Ignition in an Oxygen Control Valve

Authors: Elliot Forsyth, Jared Hooser, Nic Linley, GwenaelChiffoleau, Barry Newton

Over the years, various methods have been developed and presented for analyzing fire risk in oxygen systems and components. The analysis results are overall qualitative in nature. This qualitative approach has proven useful; however, it falls short of predicting the quantitative probability of ignition based on known factors, or characteristic elements. This paper presents a new methodology developed by WHA for estimating the quantitative probability of particle impact ignition in an oxygen control valve. The approach used, and factors considered, are presented along with the results of the quantitative probability analysis (QPA).

Share this entry

Related Articles

Battery Safety Insights with Nic Linley, Electrical Engineer

Battery technology continues to evolve rapidly in the 21st Century, powering an expanding array of devices and…

Oxygen Cylinder Filling System Fire Case Study

Oxygen cylinders and pressure systems quietly hold enormous amounts of energy. When things go wrong, the results…

Nonmetals Oxygen Compatibility Requirements: Guide to CGA/EIGA Compliance

The Compressed Gas Association (CGA) and European Industrial Gases Association (EIGA) have harmonized key documents providing guidance…

Request an expert

consultation

Contact us to request a free consultation with an experienced engineer who can help you better understand your needs and our solutions.