O2 Clean Inspection Kits

Operating a safe oxygen system starts with a clean system, one that’s free of flammable contaminants. WHA’s O2 Clean Inspection Kits are specially designed to train and assist personnel in the inspection of oxygen piping and equipment for these contaminants using methods consistent with the industry best practices.*

Both kits can be used for demonstrations as an add-on to on-site oxygen safety courses.

WHA offers a Field Inspection Kit to assist in performing visual inspection on oxygen equipment and a Classroom Teaching Kit add-on to help train personnel in visual inspection methods.

Field Inspection Kit ($1850)

The Field Inspection Kit includes industry-standard compliant tools required to perform a visual inspection on oxygen equipment, either in the field or in the lab. This includes our state-of-the-art visual inspection tools and personal protective equipment (PPE).

Benefits

1. Inspect Oxygen Piping & Equipment

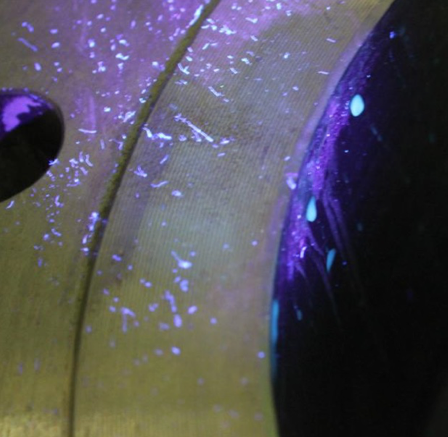

Kit provides state-of-the-art white light, black (UV) light, and wipe tests compliant with industry standards to perform qualitative visual inspection.

2. Protect Equipment and Personnel with Appropriate PPE

Provides O2 clean coveralls, gloves, glasses, and other personal protective equipment (PPE) to handle oxygen-clean hardware and protect inspection personnel.

What's Inside

Visual Inspection Tools:

- 1 x Black (UV) Light with UV safety glasses (portable high-power flashlight, output light intensity >2500µW/cm2 at 15" (38cm) with a beam diameter of 6", fixed wavelength of 365 nm optimized for hydrocarbon residues, exceeds minimum criteria from ASTM G93, CGA G-4.1, EIGA Doc 33)

- 1 x Field Inspection Cover for performing black light inspection, with magnetic clips

- 1 x White Light (portable high-power flashlight, variable-power up to 250 lumens, battery-powered, exceeds minimum criteria from ASTM G93, CGA G-4.1)

- 1 pkg of 100 Lint-free Wipes

Personal Protection Equipment (PPE):

- 1 x box of 100 Latex gloves Oxygen Clean Handling/Inspection Gloves

- 2 sets of Tyvek Laboratory Coveralls

Other Items:

- WHA VISUAL INSPECTION RESULTS FORMS (for recording results of UV light, white light, and wipe testing)

- Heavy-duty, water-proof, air-balanced Pelican™ Case with foam inserts

Classroom Teaching Kit (+$4950)

Our Classroom Teaching Kit is sold as an add-on to our Field Inspection Kit. It includes our calibration tools, solvent extraction tools, and an assortment of classroom teaching tools designed to train personnel to perform visual inspections on oxygen piping and equipment.

Benefits

3. Train Inspectors on NVR and Particle Inspection

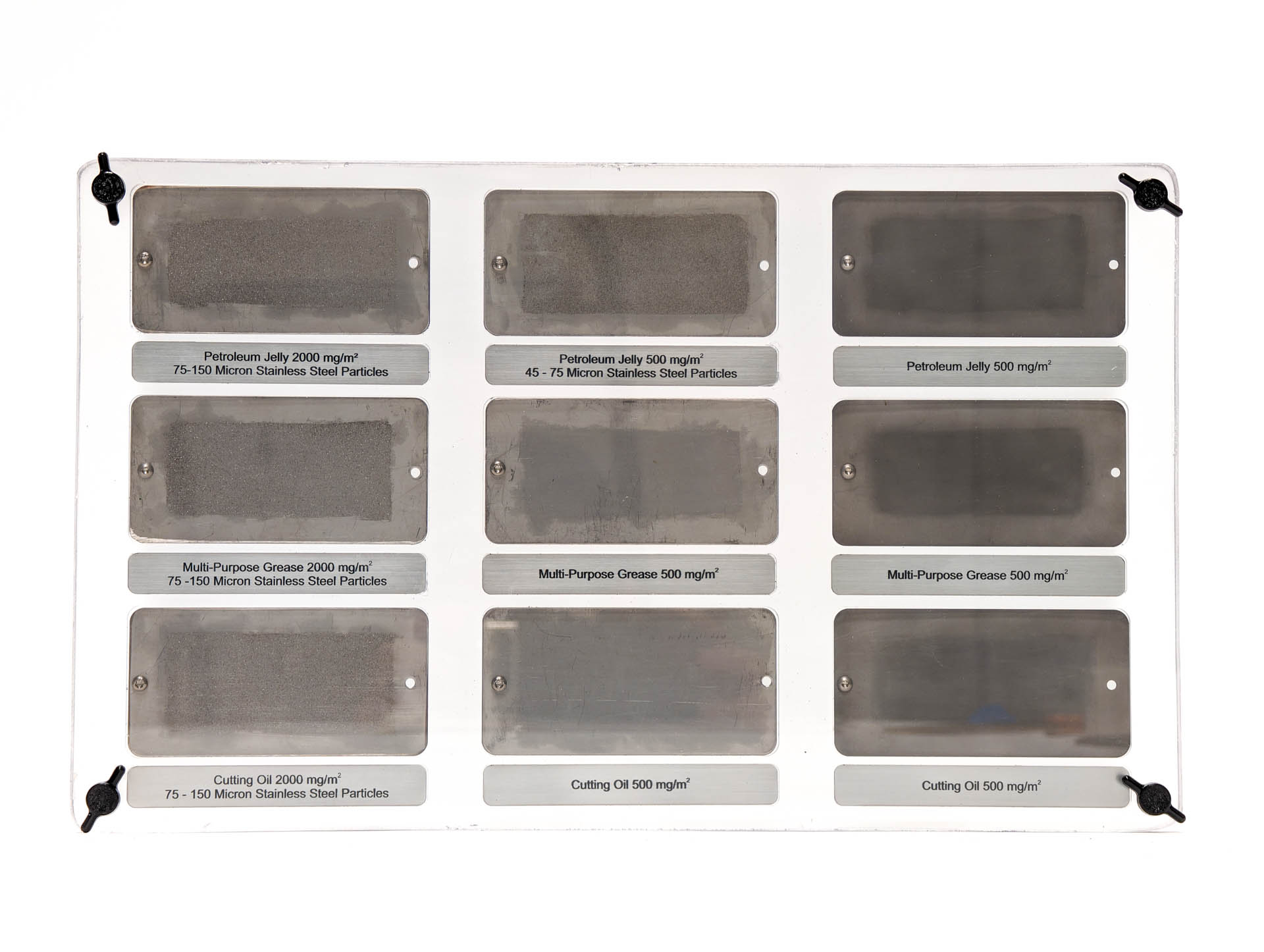

Facilitates visual inspection on stainless steel coupons contaminated with NVR and particulate examples, prepared and calibrated per ASTM G121. Carbon steel coupons are available upon request.

4. Demonstrate Solvent Inspections

Demonstrates the solvent extraction method to collect contaminants and perform a visual comparison with calibrated solvent sample set.

What's Inside

Calibration Tools

- Plate of nine (9) stainless steel coupons with calibrated quantity of hydrocarbon contaminants for NVR inspection plus control group coupon (carbon steel coupons available upon request)

- Stainless steel and iron particulate samples

Solvent Extraction Tools***

- 2 x small solvent extraction bottles

- 3 x small pipettes for application solvent transfer

Classroom Teaching Tools

- Samples of solvent mixed with hydrocarbons

- Examples of oxygen clean equipment, preserved clean in sealed plastic bags, with labels to indicate oxygen clean.

- Examples of oxygen-compatible thread tape and non-compatible thread tape.

- Example of oxygen compatible lubricant

- Examples of lint-free wipes and non-lint free wipes

Other Items:

- Heavy-duty, water-proof, air-balanced Pelican™ Case with foam inserts

*Best practices for inspecting oxygen clean parts, piping, and equipment as documented in international standards including CGA G-4.1 Cleaning Equipment for Oxygen Service (Section 11 on inspection), EIGA Doc 33 Cleaning of Equipment for Oxygen Service (Section 6 on inspection methods and acceptance criteria), ASTM G-93, Cleaning Methods and Cleanliness Levels for Material and Equipment Used in Oxygen-Enriched Environments (Section 11 on inspection), MIL-STD-1330D, Precision Cleaning and Testing of Shipboard Oxygen, Helium, Helium-Oxygen, Nitrogen, and Hydrogen Systems (Section 5.13.1 on Visual Inspection Methods), and others.

**ASTM G121 Standard Practice for Preparation of Contaminated Test Coupons for the Evaluation of Cleaning Agents

*** Solvent and solvent handling PPE is not provided in either kit and should be selected based on the guidelines in ASTM G127 and the associated SDS, respectively.

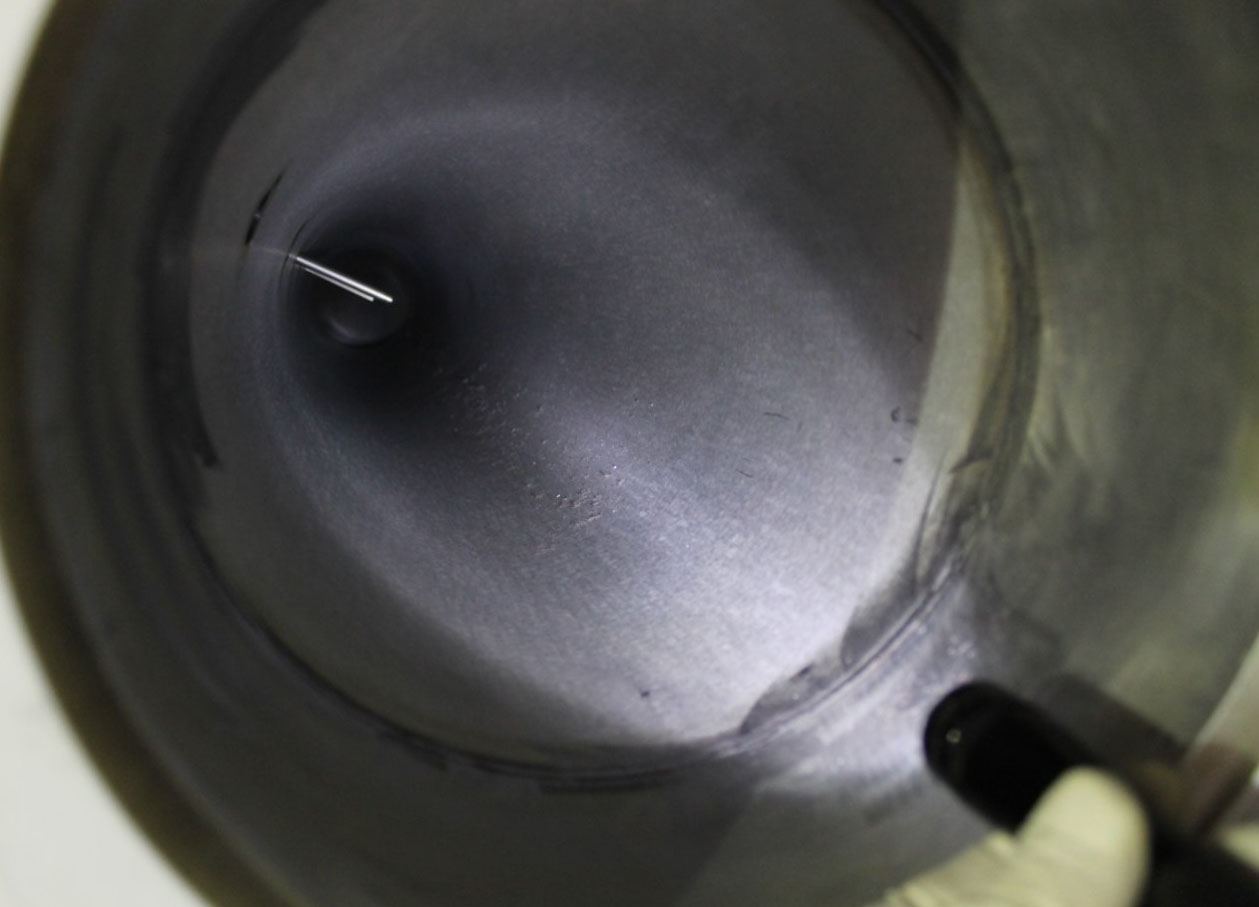

How to Use These Kits

WHA offers specific training on performing visual inspections on oxygen piping and equipment. Refer to the WHA training course catalog for more information. WHA’s training provides practical “how-to’s” regarding our oxygen clean methodology. We teach white light and black light visual inspection techniques along with the most widely used acceptance criteria from CGA G-4.1, EIGA Doc 33, ASTM G-93, and others. This training is currently offered on-site only to groups with 15 or more and is typically paired with our Level 2: O2 Practice course, which can include hands-on demonstrations of visual inspection techniques using our Classroom Teaching Kit.

Add-on: Portable Darkroom

Portable Darkroom

Upgrade to the portable, yet more permanent darkroom to optimize black light inspection. All standard kits include a custom-made black (UV) light inspection cover, but the darkroom will create an enclosed environment void of white light for higher quality visual inspections. While sturdy enough to accept power (for additional lighting), this darkroom also folds into a tote bag for the next job.

- semi-permanent

- fits one or more inspectors

- creates weather-proof environment

- accepts electrical

Add-on: Upgraded UV Light

Upgrade your UV light in the Inspection Tools to one of the most powerful field inspection lights available. It’s also highly portable and rechargeable. This state-of-the-art light provides a UV-A intensity of 18,000 µW/cm2 at a distance of 15 in (38 cm), which is more than 18 times the intensity required by most oxygen cleaning standards. Perfect for inspecting long pipelines or surfaces farther away from the light source. Comes with an AC charger, a rugged carry case, and a rubber lamp protector for durability in the field. Contact us for details.