WHA engineers receive NASA Space Flight Awareness Team Award

On May 30, 2020, SpaceX and NASA launched two Americans into space on the Demo-2 mission. It was the first astronaut launch from U.S. soil since the retirement of the Space Shuttle Program in 2011. Today NASA’s Commercial Crew Program continues to transport astronauts to and from the International Space Station (ISS) through a unique new partnership between government and commercial industry.

This progress is not without its challenges, however, and evolving technologies and applications require continual innovation and optimization.

On August 18, 2021, NASA presented a Space Flight Awareness (SFA) Team Award to a group that demonstrated exemplary teamwork in overcoming one of these challenges. Their work directly contributed to the continued success of the Commercial Crew Program.

The team included technical experts from a wide variety of disciplines and backgrounds, both within NASA and at other commercial organizations. Two team members were supplied by WHA International, Inc.: Dr. Harold Beeson and Joe Whitehead.

We spoke with Dr. Beeson to learn more about this historic award and the team’s contributions to the science of spaceflight.

Addressing key obstacles to manned spaceflight

Your award was for participation on the NASA Titanium-Nitrogen Tetroxide (Ti-NTO) Compatibility Assessment Team. That’s quite a mouthful! What was the motivation behind this special task force?

Well as you know, last year NASA resumed crewed mission launches from U.S. soil. But before that during prelaunch testing, there was an explosion of one of the new space capsules. That explosion was traced back to incompatibility between titanium and nitrogen tetroxide.

What is nitrogen tetroxide is and why is it so important to spaceflight?

NTO is an oxidizer, like oxygen, but the advantage of NTO is that it is “hypergolic.” That means it will ignite as soon as it is mixed with hydrazine fuels, with no other ignition mechanism required.

We’ve been using hydrazine type fuels with NTO for years in NASA hardware, military applications, satellite propulsion… Even in space, their ignition is very reliable, and engine performance is pretty much guaranteed.

If NTO propulsion technology is so reliable, why the sudden concern with compatibility?

This failure included a unique application with higher pressures and flow rates than what we typically see. As new applications push existing technologies like this, the science has to keep up.

“[This team’s] commitment to human space flight was exemplary… They provided outstanding technical support to the Commercial Crew Program to solve this complex issue in such a timely manner.”

Ralph Row, NASA chief engineer

Uncovering answers and developing solutions

How did your team approach this new problem?

The project, which was a joint effort between NASA and SpaceX, first included investigation of the failed hardware, allowing us to create timelines and examine how the failure may have progressed. Then we developed a strategy to mitigate those risks.

Ultimately, several problems were addressed by design and material changes, and several others were solved using new test data… In the right application, titanium can still be used. It’s very strong, light, and corrosion resistant. Other applications required different materials to sufficiently mitigate the risk.

The award spoke to a need to find solutions that were “good enough” without being overly restrictive or difficult to implement. How did your team find that balance?

That is often a challenge when evaluating risk and materials compatibility. Material test data alone can be overly conservative, but in application, compatibility is affected by numerous factors.

We performed testing at NASA and at SpaceX that was in line with how the vehicle would be operated. As a team, we developed modeling software and were able to confirm the model with testing. This allowed us to run more iterations and find solutions more quickly.

You and WHA Engineer Joe Whitehead both participated on the team; what were your particular roles?

My role on the team began with failure analysis and data review. I was also part of the group that performed the NTO Compatibility Assessment (NTOCA), which is very similar to the OFRA process that WHA uses for oxygen.

Joe was responsible for designing various pieces of test hardware, and he was also involved in coordination of a lot of the report activities… He created some extremely unique hardware that was able to seal at high pressures but also allow us to film what was happening inside. These visualizations were key to helping us understand what was going on in terms of flow dynamics.

Advancing the science of spaceflight

Was there anything that surprised you about this project?

This project brought several fundamental assumptions about oxygen systems into question—and in several cases disproved them.

For one, particle impact ignition is generally not considered to be a significant risk for liquid oxygen systems. In this application we were seeing particle impact ignitions with NTO in liquid and vapor and gas phase—and all kinds of different scenarios.

There is also an assumption that says if you dilute your oxidizer with a little bit of inert gas (i.e. helium or nitrogen) you greatly reduce the flammability of metals. In this case we did not see that big reduction we expected to see. The addition of inert gases did not significantly impact compatibility.

How will these findings affect the safety of rocket propulsion systems moving forward?

This was definitely an enlightening experience for continued work with special oxidizers like NTO. Our findings actually influenced a key modification to NASA materials and processes guidance, which previously only required an O2 compatibility assessment. Now it states you have to do a separate compatibility assessment with test data that is unique to each oxidizer involved.

Now that you have concluded the project and seen American astronauts successfully launched into space once again, what are your impressions on the whole experience?

One of my sayings that I really like is that “none of us is as smart as all of us.” I think that really applies to this team. Each person brought their own unique expertise and ideas to the table, none of which were singularly the answer to the problem. As we worked through those ideas as a team and applied that expertise to the problem it worked out very well.

It is an honor to be receiving this award, and it was just a really neat experience.

“Because of teams like yours, we are able to fly safely and complete our objectives on a daily basis… we can’t do these difficult tasks without assistance from one another.”

NASA Astronaut Megan McArthur

Share this entry

Related Articles

Battery Safety Insights with Nic Linley, Electrical Engineer

Battery technology continues to evolve rapidly in the 21st Century, powering an expanding array of devices and…

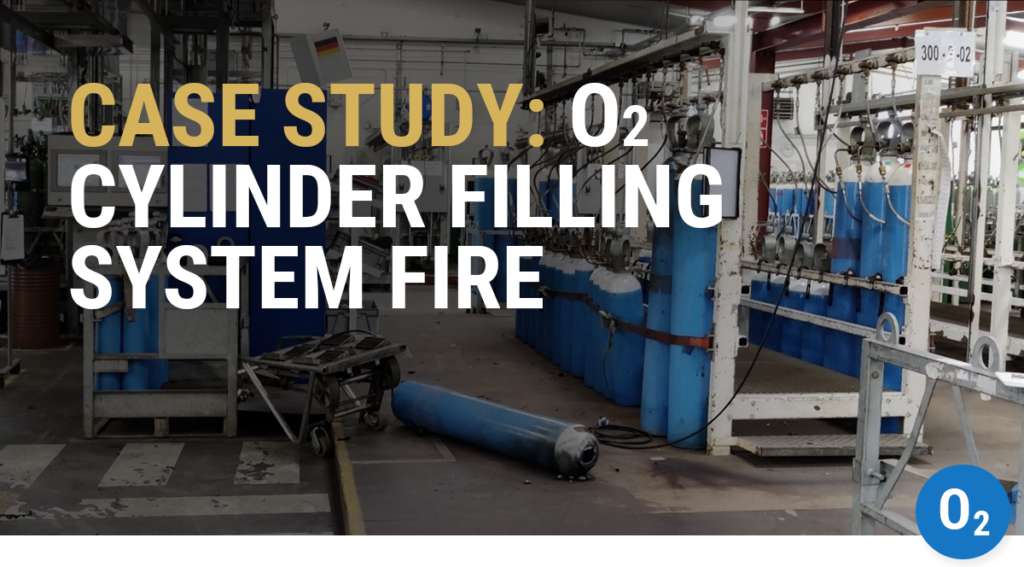

Oxygen Cylinder Filling System Fire Case Study

Oxygen cylinders and pressure systems quietly hold enormous amounts of energy. When things go wrong, the results…

WHA Presents O2 Safety Papers at 2024 ASTM G04 Symposium

In October 2024, Gwenael Chiffoleau, Nic Linley, and Brent Houser traveled to Prague for the 16th ASTM…

Request an expert

consultation

Contact us to request a free consultation with an experienced engineer who can help you better understand your needs and our solutions.