We go Beyond the Results

WHA’s test facilities are internationally recognized for the range and depth of their testing capabilities and research services. Our lab offers tests for many international standards as well as state-of-the-art specialty tests unique to WHA. WHA is renowned for its quality custom-tailored testing and its ability to deliver fast results.

Our extensive background in failure analysis, hazard analysis, and industry standards development, allows us to help you understand potential hazards and fire risks for your components and recommend any necessary or beneficial testing. We provide more than just technical results, and can also offer consulting to help your components meet the requirements for regulations, standards, and safety. WHA standard testing services are accredited to ISO 17025 and are within the scope of our ISO 9001 certification.

Oxygen Component Qualification

Component qualification tests are used to help determine if critical equipment is safe to use in oxygen systems. Requirements are set by numerous international standards, including ASTM, ISO, CGA, and EN. Our services include tests like oxygen pressure surge test, promoted ignition test, and more.

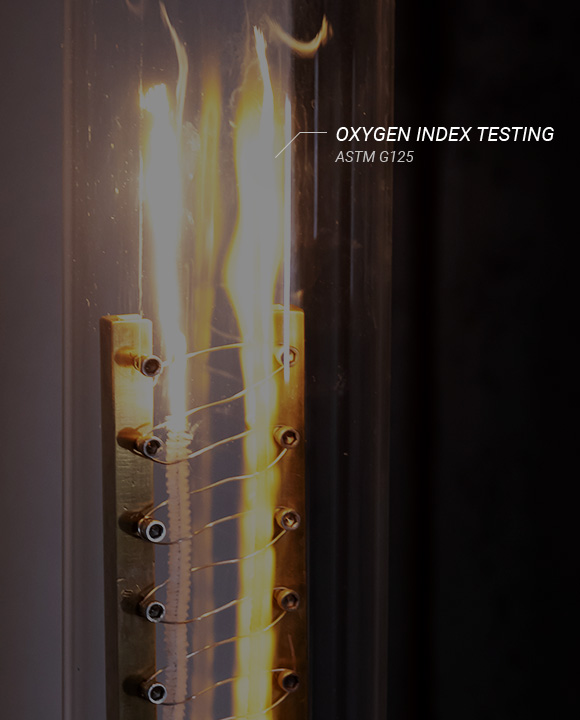

Oxygen Compatibility Testing

Compatibility tests are used to determine if specific materials are safe for use with oxygen. The results primarily help inform manufacturers designing components for use in oxygen systems. International standards for compatibility are defined by organizations, including ASTM and ISO. Our services include metals tests such as promoted combustion of metals and nonmetals tests like autogenous ignition temperature, gaseous fluid impact sensitivity, mechanical impact and more.

Conformance testing is provided for manufacturers that wish to certify components for accreditation, including a CE mark or a Pi (π) stamp. Conformance testing is also known as type testing and compliance testing. Common conformance tests measure component aspects like ignition, excessive torque, leak tightness at high and low temperatures, endurance, and more.

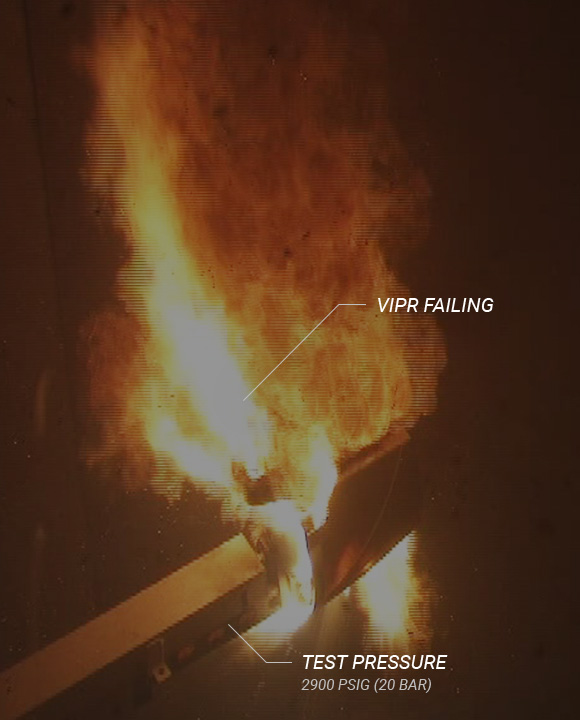

Custom Testing and High Energy Testing

Our custom test services provide solutions when clients’ needs exceed the requirements defined by established standards. We can offer a range of original tests unique to WHA, and whenever necessary, our experienced engineers are also capable of developing entirely new test systems to meet your needs. Over decades of experience, several of our past custom tests have actually evolved into industry standards, influencing new tests and regulations around the world. Custom tests can include high-energy testing, performed at the WHA Proving Ground, our large-scale, safety-engineered testing area. We also have a unique industry liaison relationship with NASA’s White Sands Test Facility, providing testing solutions that exceed our own in-house capabilities.

We Set the Standards

New and innovative testing systems are routinely developed based on specific customer requirements and evolving industry-specific demands. Along with its own facility, WHA, through a unique industry liaison relationship with NASA’s White Sands Test Facility, makes available testing capabilities that exceed WHA’s in-house capabilities. Using unparalleled facilities and test systems, we provide clients with tests defined by standards organizations, including ASTM International, International Standards Organization (ISO), and Compressed Gas Association (CGA). As leaders or contributors to these standards review committees, WHA engineers and scientists are intimately familiar with and actively involved with developing these standards.