Cleanliness Evaluation

Our OCV is performed with solvent extraction methods according to ASTM standards and is capable of providing non-volatile residue (NVR) amounts (e.g., mg/ft2 or mg/m2) and particle sizing/counting/mass. If necessary, the extracted contaminants can also undergo material characterization at WHA, using techniques such as FTIR spectroscopy and EDX spectroscopy to determine the type and origin of the contamination. With strategic sampling of a system and contamination mapping, the source of the contamination can also be determined. These services can be paired with our oxygen fire risk analysis to help evaluate the need for re-cleaning.

WHA is capable of evaluating to oxygen cleaning specifications in standards such as ISO 15001, ASTM G93, EIGA Doc. 33, CGA 4.1, MIL-1330D, and SAE ARP1176.

Oxygen CleaningTraining Solutions

As an industry leader in oxygen safety, we often pair our cleaning services with technical training solutions. Our customizable packages can include training tools and modules on oxygen cleaning to equip your staff.

Latest Industry Insights

Hydrogen Cleaning: Ensuring Safety and Reliability in Pressurized Hydrogen Systems

Hydrogen is an increasingly important and prominent energy carrier, with applications ranging from fuel cells to electrolyzers…

Battery Safety Insights with Nic Linley, Electrical Engineer

Battery technology continues to evolve rapidly in the 21st Century, powering an expanding array of devices and…

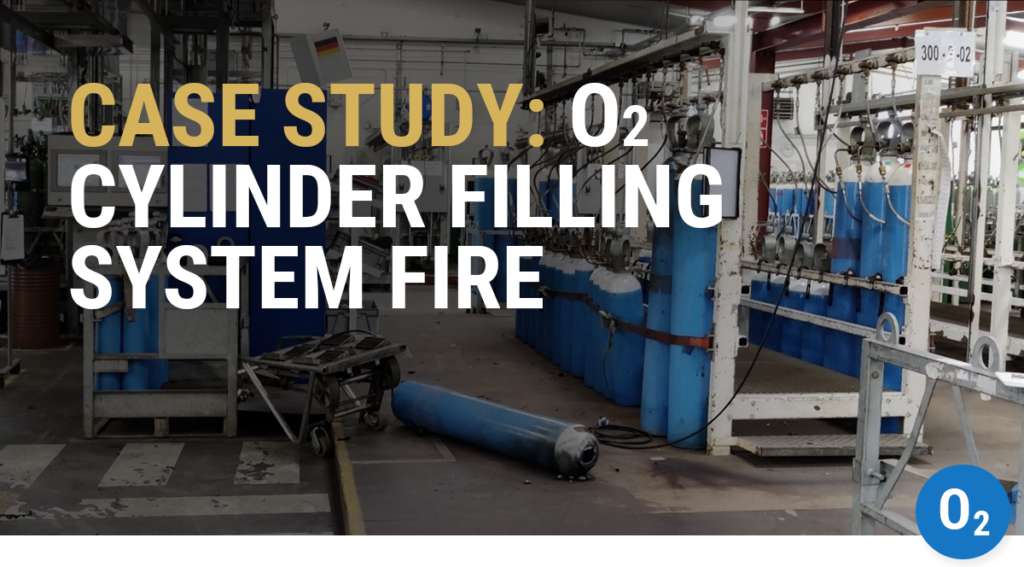

Oxygen Cylinder Filling System Fire Case Study

Oxygen cylinders and pressure systems quietly hold enormous amounts of energy. When things go wrong, the results…