New test explores how material thickness affects flammability

Because materials can ignite and burn more easily in oxygen-enriched atmospheres, they undergo a battery of standardized tests to see how they will perform in oxygen service. Flammability is affected by different application-specific factors, like pressure, temperature, and oxygen concentrations.

Although these tests are quite thorough, there is still a gap in quality data concerning one unique factor affecting flammability: material thickness.

In response, the oxygen safety engineers at WHA International have developed a new test configuration to capture valuable new data and help keep industry safe.

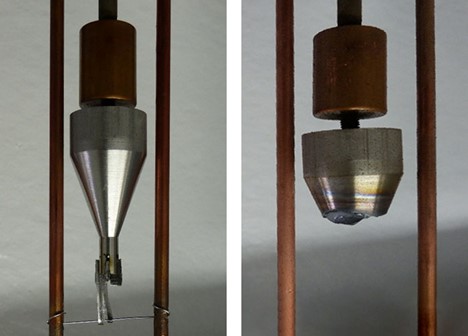

WHA’s new test method utilizes a tapered metal rod to help determine “extinguishment diameter.” In this test video, the tapered rod has been outlined to aid in visibility.

How Thickness Affects Flammability

Thinner objects can ignite and burn easily, while thicker ones may self-extinguish.

“As thickness increases, there is more volume of material to receive the combustion energy,” explains Senior Oxygen Safety Engineer Gwenael Chiffoleau, Ph. D., who helped coordinate this project. “This causes the material to extinguish as there is too much heat loss.”

If you have ever built a campfire, you have seen this principle in action. A wooden match will burn easily and can kindle fire to other small twigs, but it can’t directly kindle fire to a large log. Both objects consist of the same material (wood), but their flammability is determined by their thickness.

ASTM G124 and Basic Metals Compatibility Testing

Engineers know qualitatively that thickness impacts flammability, but they don’t yet have an established test standard to provide more applicable, real-world data.

For a basic understanding of metal thickness, component designers primarily look to the standard test ASTM G124. In this test, a sample rod (3.2 diameter) is attached to an ignition promoter and exposed to 100% oxygen at variable pressures.

“When you think of a big valve, there’s really no application in that valve of a 3.2 mm rod suspended in oxygen” explains Gwenael. “The actual geometries are very different — they may be a lot thicker. As material selection engineers we’ve always struggled to apply this test directly.”

“The setup helps explore how pressure affects flammability, but it’s not designed to examine thickness, unless a batch of testing is performed with sample diameters representing each thickness of interest. This is not typically an economical approach because many tests are required,” adds Jared Hooser, another WHA oxygen safety engineer who worked on the project.

In order to maintain safety and maximize material performance, engineers need better data to understand how thickness affects flammability.

https://player.vimeo.com/video/528404585

ASTM G124 is a standard test that examines material compatibility for oxygen service. A vertical 3.2mm sample is suspended in an oxygen atmosphere at various pressures and ignited using a special promoter.

Developing a New Test Configuration

To help gather better data, engineers at WHA have begun to develop a new oxygen test — a variation of ASTM G124.

“We have come up with a new term, what we’re calling extinguishment diameter,” shares Gwenael. “Instead of figuring out what pressure a material burns at, we’re keeping the pressure constant and figuring out at what diameter the sample will self-extinguish.”

The new test features a metal test sample with a conical geometry of tapered thickness. Using the same promoter technology as ASTM G124, the test ignites the tip of the metal cone and lets it burn upwards. As thickness increases, there is more material to absorb combustion energy, and eventually the fire will extinguish.

“We tested several different alloys and different angles, trying to find the optimal shape of the cone,” says Jared. “Instead of testing multiple different rods, we’re trying to come up with a single configuration that gives us more answers.”

| Arbitrary Alloy Designation | Test Sample Max Diam (mm) | Test Pressure (MPa) | Number of Tests | Taper Angle (deg) | Extinguishment Diam (avg ± std dev) (mm) |

| A | 20 | 6.30 | 5 | 62.6 | 7.3 ± 2.4 |

| B | 9.5 | 13.79 | 10 | 80.5 | 7.0 ± 0.5 |

| B | 12.7 | 13.79 | 10 | 76 | 6.7 ± 0.5 |

| C | 12.7 | 3.45-6.89 | 5 | 76 | 7.5 ± 2.9 |

| C | 15.9 | 6.89-8.62 | 5 | 73 | 10.1 ± 2.1 |

| C | 15.9 | 8.62-10.34 | 4 | 73 | 12.6 ± 3.0 |

| C | 22.2 | 13.79-17.24 | 5 | 70 | 17.7 ± 1.9 |

Example of Extinguishment Diameters for various arbitrary alloys

Next Steps for the New Test

With the custom test configuration, WHA’s test team was able to successfully generate new data about material thickness, and they have submitted their findings in a new technical paper presented to ASTM.

“While we are confident in the concept, it’s very much an exploratory paper. The work showed that there is more experimentation that needs to be done before it can be considered for a test standard,” explains Gwenael.

Through further research, the team hopes to refine a test that would provide valuable supplemental information for component designers.

For more information on the topic, see the upcoming article to be published by ASTM, “Evaluation of Metals Flammability Using Extinguishment Thickness” by Jared Hooser, Gwenael Chiffoleau, Elliot Forsyth, Barry Newton of WHA International, in partnership with James White and Eric Thom of Praxair, Inc., a member of the Linde group.

Options for Industry to Examine Risk and Material Compatibility

If you would like to learn more about how material selection affects the flammability of your oxygen components and systems, WHA offers a variety of hazard analysis and oxygen compatibility testing services.

Although this new test is still in development, it is already being used to generate valuable metals flammability test data, and WHA is currently welcoming industry partners who wish to further explore the concept for their own applications.

Share this entry

Related Articles

Battery Safety Insights with Nic Linley, Electrical Engineer

Battery technology continues to evolve rapidly in the 21st Century, powering an expanding array of devices and…

Oxygen Cylinder Filling System Fire Case Study

Oxygen cylinders and pressure systems quietly hold enormous amounts of energy. When things go wrong, the results…

WHA Presents O2 Safety Papers at 2024 ASTM G04 Symposium

In October 2024, Gwenael Chiffoleau, Nic Linley, and Brent Houser traveled to Prague for the 16th ASTM…

Request an expert

consultation

Contact us to request a free consultation with an experienced engineer who can help you better understand your needs and our solutions.