WHA engineers have oxygen fire expertise unparalleled in industry, spanning nearly all industries that use oxygen and other non-oxygen oxidizers. We know oxygen fires like no one else.

WHA engineers take the mystery out of oxygen fires using their unparalleled oxygen fire expertise, spanning nearly all industries that use oxygen and other non-oxygen oxidizers. Beginning in the 1980s, WHA engineers have provided oxygen compatibility guidance, training, and failure analysis for the aerospace, welding, commercial gas, petrochemical, medical oxygen, and medical device industries. WHA has investigated hundreds of fires and incidents in most industries that use oxygen and have developed tools to harden systems against oxygen-related fire hazards.

- WHA has extensive oxygen safety and failure analysis expertise and provides services worldwide. WHA’s oxygen technologies uniquely sets WHA apart from virtually all other commercial firms in our industry.

- WHA brings NASA’s oxygen expertise to commercial industry. WHA engineers were among the NASA engineers that designed, fabricated, and implemented many of the oxygen and hazardous fluids test systems used by the space program during the Apollo, Space Shuttle, and International Space Station programs. WHA engineers participated in the qualification of many flight hardware systems and materials compatibility screening tests performed in support of the first 117 NASA Space Shuttle flights.

- WHA’s oxygen experience spans nearly every industry that uses oxygen. Beginning in the late 1980s, WHA engineers provided oxygen compatibility guidance, training and failure analysis for the aerospace, welding, commercial gas, petrochemical, medical oxygen and medical device industries. WHA has investigated fires and incidents in most industries that use oxygen and has developed tools to harden systems against oxygen-related fire hazards.

- WHA’s oxygen hazards and fire risk training is unsurpassed in the industry. WHA specializes in custom-tailored, technical training for oxygen systems and stresses the “why” behind the “what” related to mitigating fires in oxygen systems. Our engineers pioneered the development of oxygen safety training at NASA and ASTM International and today have advanced the content and methods well beyond any other government or industry source.

- WHA engineers have led the development of many international standards on oxygen safety. WHA engineers were founding members of the important ASTM International G-04 committee on Flammability and Sensitivity of Materials in Oxygen-Enriched Atmospheres. WHA engineers are also designated experts on ISO committees, NFPA committees, and the Undersea & Hyperbaric Medical Society.

- WHA test laboratories are unique and highly specialized for oxygen compatibility testing and material/component qualification. The WHA test facility has been utilized by clients throughout the world and is recognized among the leading test facilities for excellence in oxygen testing for both failure reconstruction testing and material, component, and system risk mitigation.

Oxygen Equipment Experience

Oxygen Production, storage, and distribution systems

- Air separation plants

- Liquid oxygen bulk storage and portable systems

- Pipeline applications

- Compressor systems

- Cryogenic liquid oxygen pumps

- Packaged gases (compressed oxygen cylinders)

Industrial oxygen systems

- Mining and minerals processing

- Petro-chemical production plants

- Metals recycling and steel mills

- Petroleum Gas-to-liquid (GTL) plants

- Welding/cutting equipment (welding regulators, oxy-acetylene torches, welding hoses)

- Oxygen cylinder gas filling facilities

- Cylinder supply and distribution systems

- Cylinder valves, flexible hoses, manifold systems

- Reactor systems

- Syngas production systems

Medical oxygen systems

- Concentrators, conservers, and ventilators

- Valves, regulators, and valve-integrated regulators

- Portable cryogenic liquid oxygen containers

- Hyperbaric systems

- Neonatal systems

- Hospital oxygen systems

Aerospace and aircraft systems

- Commercial and government spaceflight vehicle systems

- Flight and ground support equipment

- Passenger /pilot oxygen systems

Military and recreational diving systems

- Diving equipment, including technical diving and rebreather systems

- SCUBA filling systems (including oxygen and NITROX)

Nitrous Oxide Experience

- Medical equipment and device hazards analysis and failure analysis

- Medical device and cylinder valve rapid compression testing

- Cylinder rupture analysis due to nitrous decomposition

- Nitrous oxide decomposition and reactivity testing

- Nitrous oxide minimum ignition energy testing

- Nitrous oxide filling and transfer systems

- Metal and non-metal material ignition testing (AIT, mechanical impact, particle impact) in nitrous oxide

Other Oxidizer Experience

- Gaseous and liquid oxygen (GOX & LOX)

- Nitrous oxide (N2O)

- Nitric Oxide (NO)

- Nitrogen dioxide/nitrogen tetroxide (NO2/N2O4)

- Nitrogen trifluoride (NF3)

- Nitric acid

- Ozone

- High pressure compressed air

Oxygen Testing & Incident Reconstruction

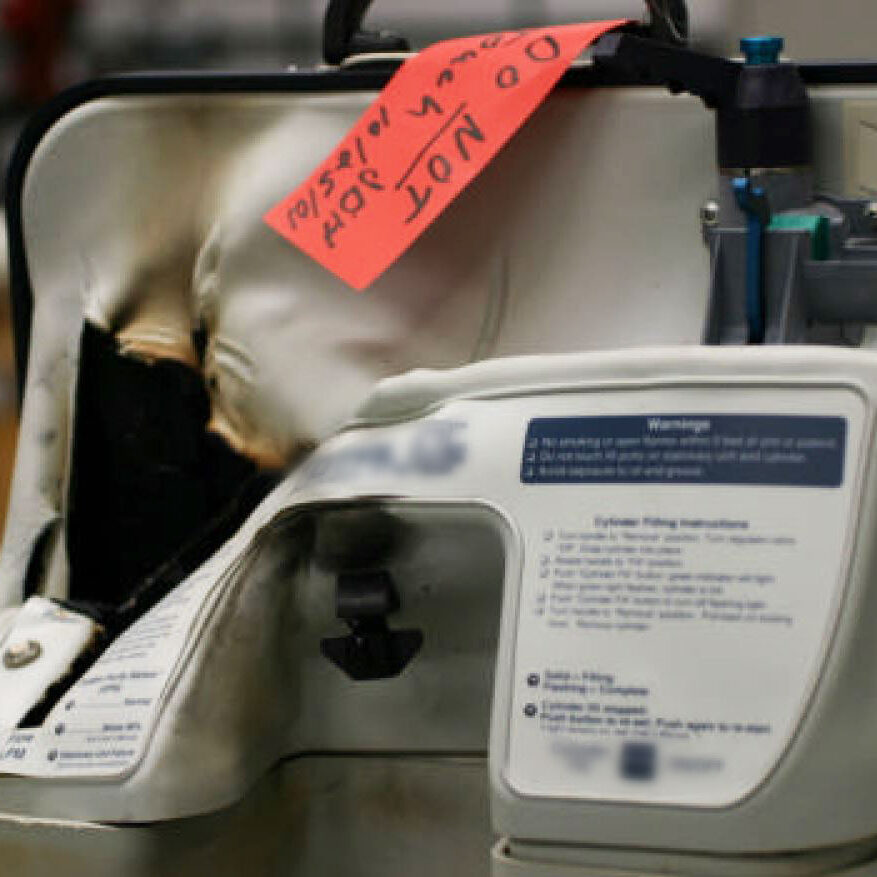

The aftermath of fire is often chaotic, messy, and confusing, but our meticulous approach is designed to eliminate the mystery. We do everything possible to uncover clear answers and actionable recommendations. Our findings are based on thorough forensic engineering, often including state of the art testing and accident reconstruction.

Oxygen Industry Insights & Case Studies

WHA Failure Analysis Legacy: Lessons Learned in Forensic Engineering

What are some of the biggest lessons you’ve learned through forensic engineering? Brad Forsyth: Our failure analysis…

Enhanced Support for Pressure System Design

With over 35 years in the industry, WHA has established itself as a leader in investigating and…

New Training for Oxygen Equipment Cleaning and Compliance

In oxygen-enriched environments, even microscopic particles or residues can lead to a fire. That’s why international standards…