Specialized

Capabilities

We investigate fires, explosions, and failures of systems and components using oxygen, hydrogen, other hazardous fluids, or pressure equipment. From small medical oxygen equipment to large petrochemical plant explosions, we have the expertise and tools to determine what went wrong.

Oxygen Failures

Investigate fires related to oxygen and other oxidizers.

Hydrogen Failures

Investigate fires and explosions related to hydrogen.

Hazardous Fluids

Investigate fires and incidents related to toxic or reactive gases.

Fuel Gases

Investigate fires related to a wide range of fuel gases.

Pressure Equipment

Investigate ruptures, leaks, and mechanical failures related to pressurized systems.

Electrical Devices

Investigate fires in electrical medical oxygen devices and other electrical systems.

Forensic Investigation

Investigate and document the scene of an incident in preparation for litigation.

Expert Witness

Utilize our experience and data-driven insights in legal contexts.

Subject Matter Experts

WHA’s engineers are recognized among the world’s leading experts in incident investigations involving oxygen and other hazardous fluids. We’ve analyzed hundreds of incidents, from small medical device fires to large industrial explosions. Our findings have frequently influenced the industry, leading directly to new international standards that continue to save lives and protect property around the globe.

Strength in Numbers

Fires and explosions are typically a once-in-a-lifetime traumatic event, but we deal with these incidents every day. Our experience and unique capabilities will bring understanding to your failure incident related to oxygen or other hazardous fluids.

0+

years combined experience0+

fire incidents investigated0+

countries servedCustom Testing & Incident Reproduction

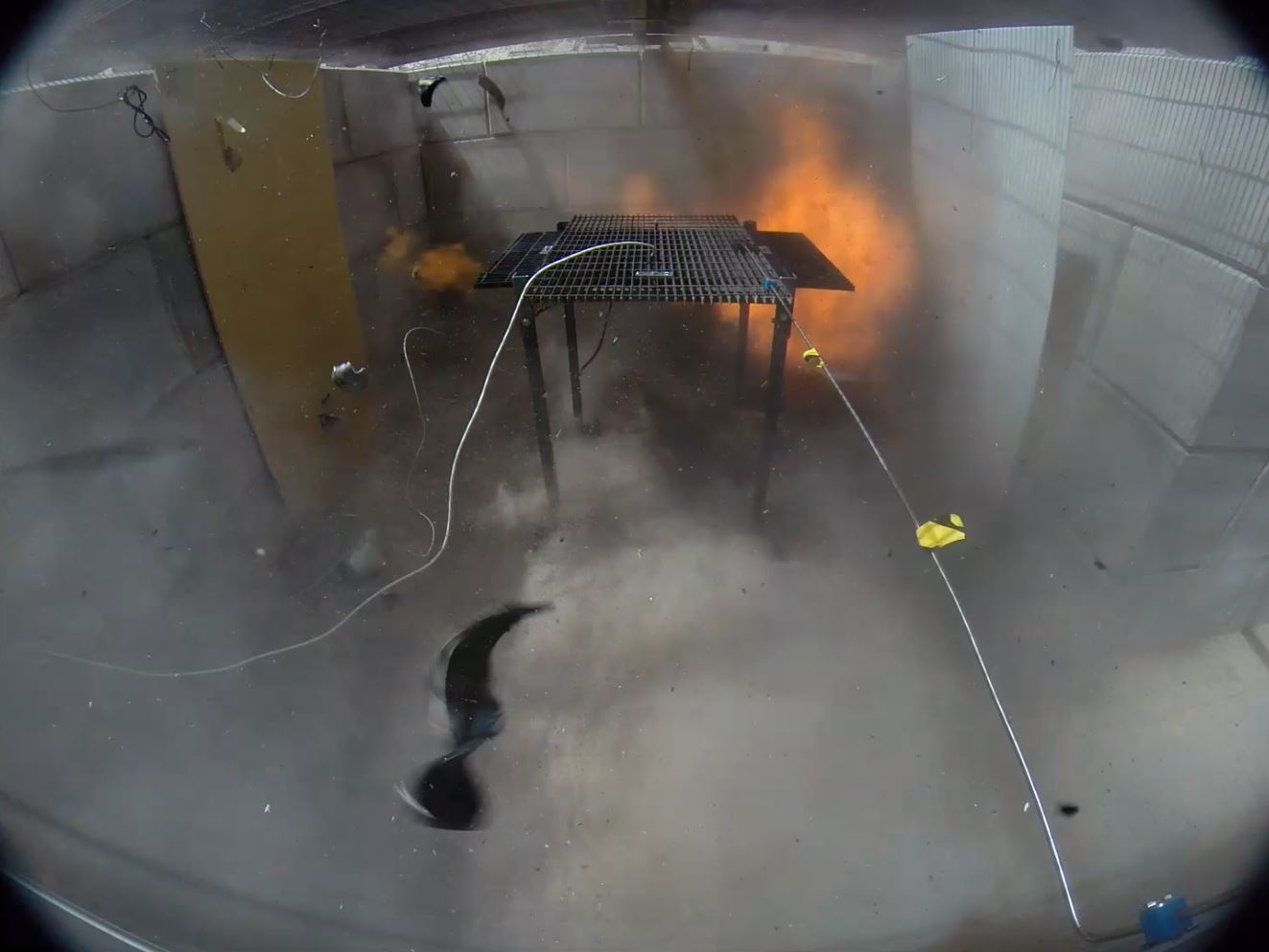

Our team is uniquely qualified to develop custom test methods that can provide data-driven insights about a failure.

At our Test and Training Center in Las Cruces, New Mexico, we've performed tests on everything from small medical oxygen valves to violent ruptures of large industrial gas cylinders.

Actionable Insights Enhance Safety

Our failure analysis experts go far beyond conjecture to find defensible answers based on facts and verifiable data — actionable insights our clients can use to enhance safety and prevent future incidents.

In fact, our findings have frequently influenced the industry, leading directly to new international standards that continue to save lives and protect property around the globe.

Failure Analysis Case Studies

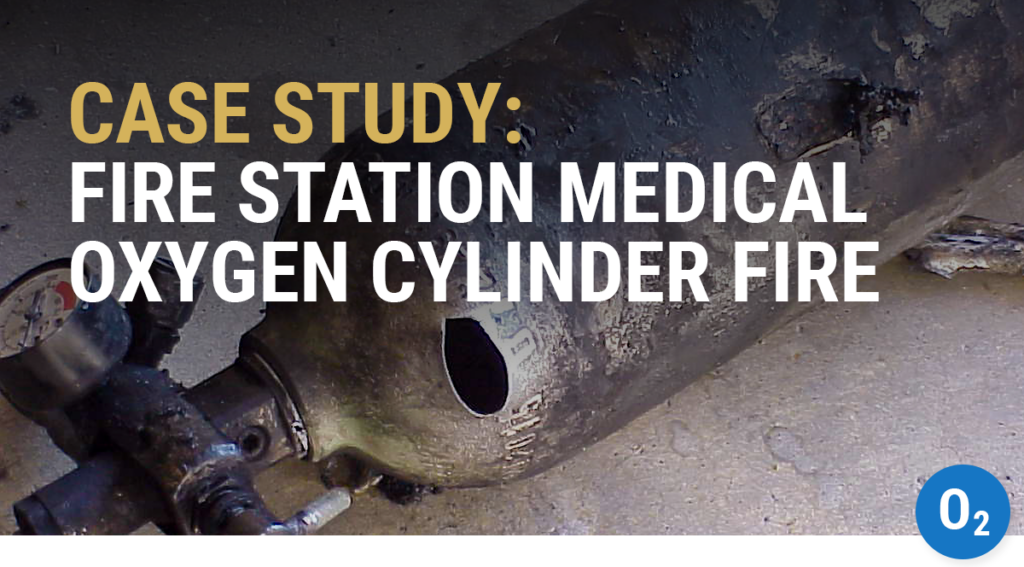

Case Study: Fire Station Medical Oxygen Cylinder Fire

A medical oxygen cylinder experienced a catastrophic failure and burnout during a routine fire station equipment check

Real world oxygen fire evidence underscores the need for safety

Over 30+ years of investigating oxygen fires at WHA International, Inc., we have documented hundreds of incidents and related fire-damaged artifacts.

Case Study: Aluminum Oxygen Tank Fires Initiated by Impact

In recent years, several notable oxygen tank fires have occurred after a fall or sudden impact. WHA is actively investigating what went wrong.